Estudio de caso: Prevención de fallas en el motor de la bomba de lodo mediante detección temprana con DataMind AI™

enero 8, 2026

Overview

Razor Labs DataMind AI™ was monitoring critical rotating equipment at a vanadium mining site, including one of the site’s main slurry pumps. This pump is a critical component in one of the site’s two parallel processing lines. A failure would have forced a shutdown of the entire line, resulting in the loss of 50% of the site’s production capacity.

From the moment of deployment, DataMind AI™ flagged the pump motor as ״Alarm״, due to abnormally high and consistent friction indicators. Despite no operational symptoms at that stage, such as temperature increase or pressure drop – the system identified irregular vibration and friction patterns not typical for this pump.

The site team verified that the lubrication system was functioning correctly, and when no improvement was observed, they reduced the pump load to 60% in an attempt to stabilize its condition and prolong its life. DataMind AI™, however, continued reporting abnormal friction. These AI-driven insights prompted the team to order spare parts in advance. Toward the end of the month, when the parts arrived, the team conducted a planned shutdown and replaced the motor. Upon removal, a visible crack was discovered in the motor shaft – validating the early warning and confirming that failure had been imminent.

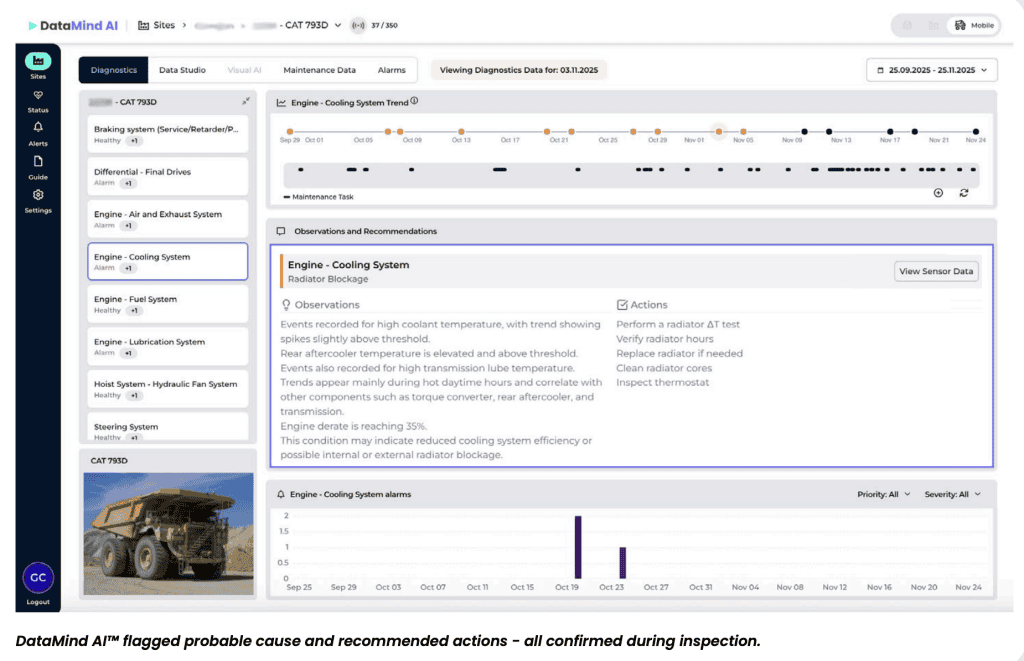

DataMind AI Diagnostic Methology

Detection & Diagnosis

DataMind AI™ monitored and classified the pump motor as high-risk based on:

- Persistently high-frequency vibration across all loads, indicative of friction

- Current and speed indicate that the motor was not operating under high load

Diagnosis

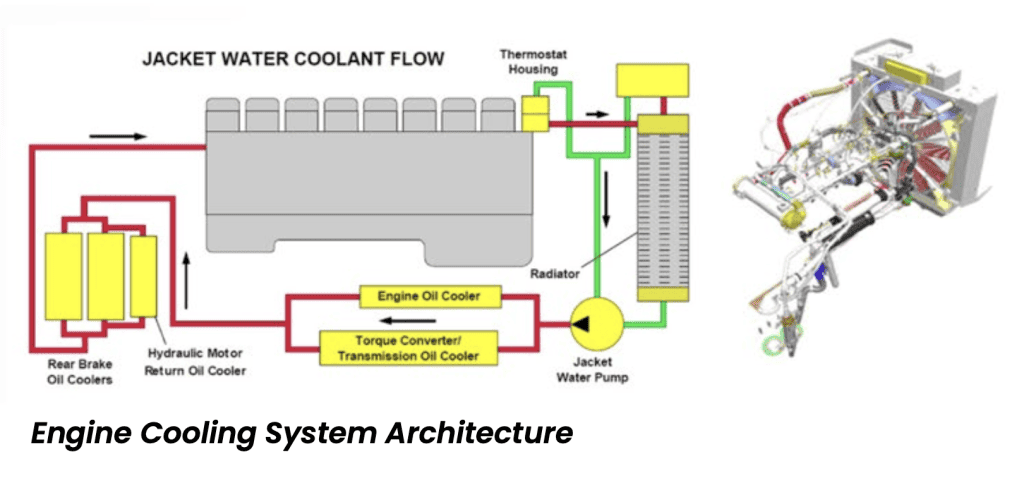

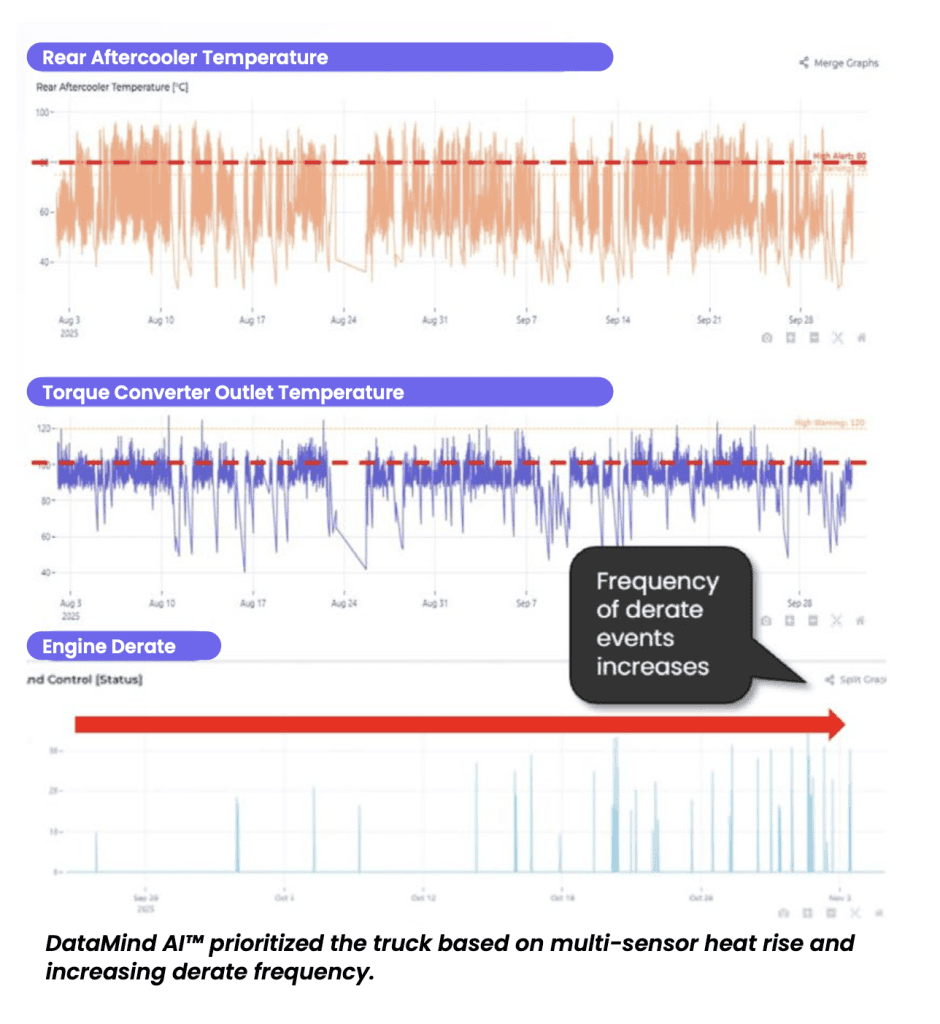

- Simultaneous temperature rise across key cooling components.

- Linked to frequent derate events during loaded operation.

- Ruled out single-sensor error, confirming true mechanical degradation.

- Root cause identified: reduced cooling efficiency due to internal or external radiator blockage.

This pattern was detected across the torque converter, rear aftercooler, engine coolant, and transmission lube – especially during throttle spikes under load.

DataMind AI™ connected these signals to surface the true failure mode before breakdown.

Before vs. After Replacement – Friction Resolved

Before replacement: Persistent high vibration levels linked to friction, even under reduced load

After replacement: Vibration levels returned to nominal ranges expected for this pump type

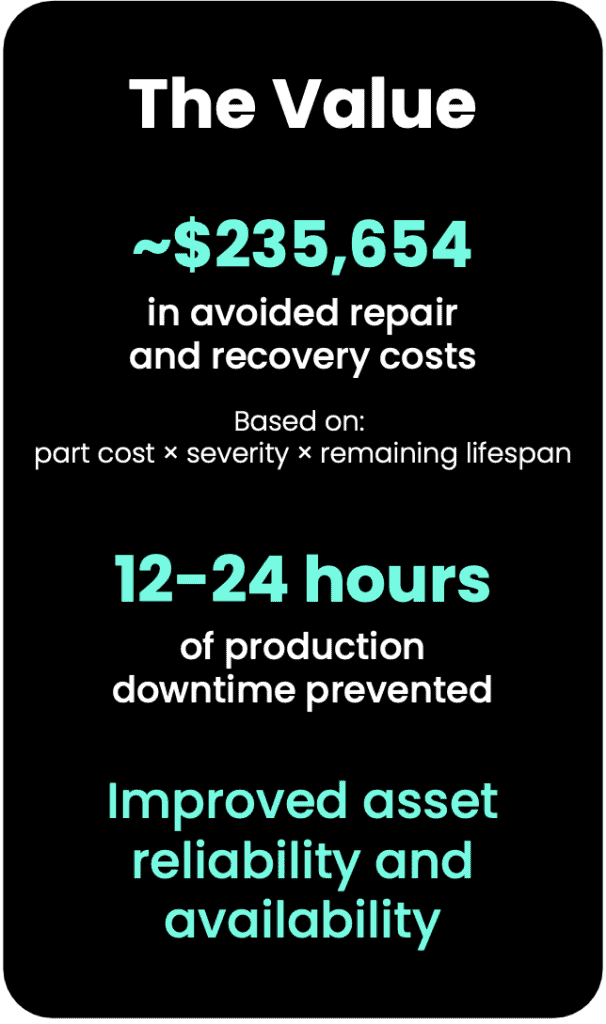

Results

- Zero unplanned downtime

- Radiator degradation detected early – before impact on performance

- Continuous production maintained without operational disruption

- Improved ConMon efficiency by eliminating false alarms and noise

Summary

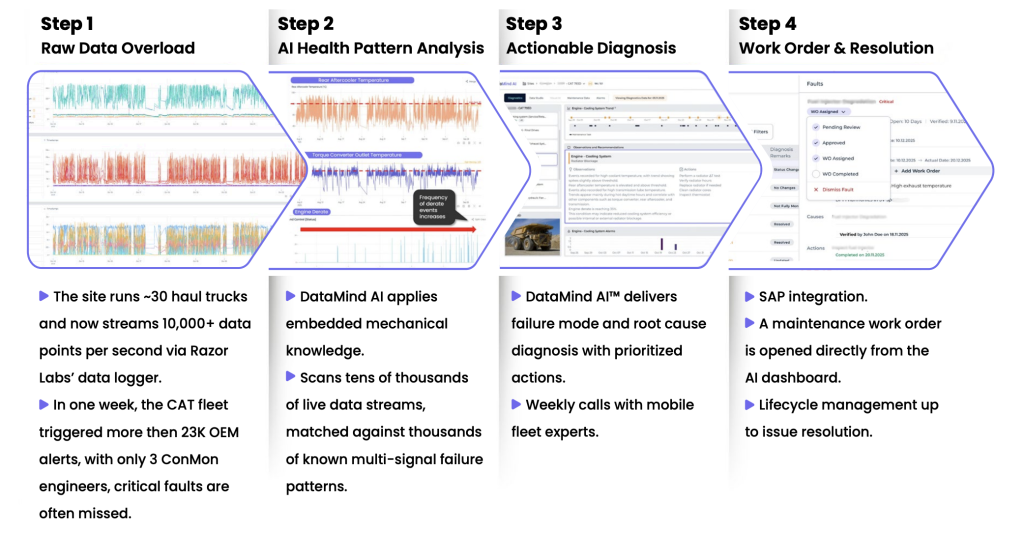

In large mining operations, where fleets generate thousands of OEM alerts weekly, it’s easy for real mechanical issues to get buried in the noise.

This case highlights how DataMind AI™ goes beyond traditional monitoring, cutting through the alert overload to detect the true root cause of faults.