Estudio de Caso: Detección de Problemas de Lubricación de Rodamientos en un Compresor con DataMind AI™

By Razor Labs 7 min read SHARE Overview At a major coal mining site, DataMind AI™ was deployed to monitor critical equipment, including compressors essential for plant auxiliary operations. After the deployment, the system flagged one compressor’s drive-end bearing for abnormal vibration levels – well above those observed in identical units. While traditional tools may […]

Fragmento de Estudio de Caso: Fusión de Sensores Identifica Degradación Mecánica en Ventilador de Sinter Antes de la Falla

By Razor Labs 5 min read SHARE Unexpected sinter fan failures in alloys production can cause major operational downtime and financial losses. To avoid these risks, a leading site implemented DataMind AI™ to monitor critical equipment in real time and flag early signs of mechanical deterioration. In early March 2025, DataMind AI™ detected elevated axial […]

PODCAST: Razor Labs en IoT For All – IA e IoT en la Industria Minera

by Razor Labs 5 min read SHARE In this episode of the IoT For All Podcast, Razor Labs’ CTO & Co-Founder Michael Zolotov joins host Ryan Chacon to discuss how AI and IoT are reshaping predictive maintenance in one of the world’s toughest industries – mining. Michael shares how DataMind AI™ leverages multi-source sensor data […]

Razor Labs en GRX25: Una conversación sobre innovación minera con Mark Warren

by Razor Labs 3 min read SHARE In this exclusive GRX25 interview, Andrew Kaushal (VP Sales) sits down with Mark Warren, Corporate Executive Consultant at Snowden Optiro, to discuss the evolving collaboration between miners, METS, and tech providers. Together, they explore the challenges of adopting AI and predictive maintenance, and the practical steps mining companies […]

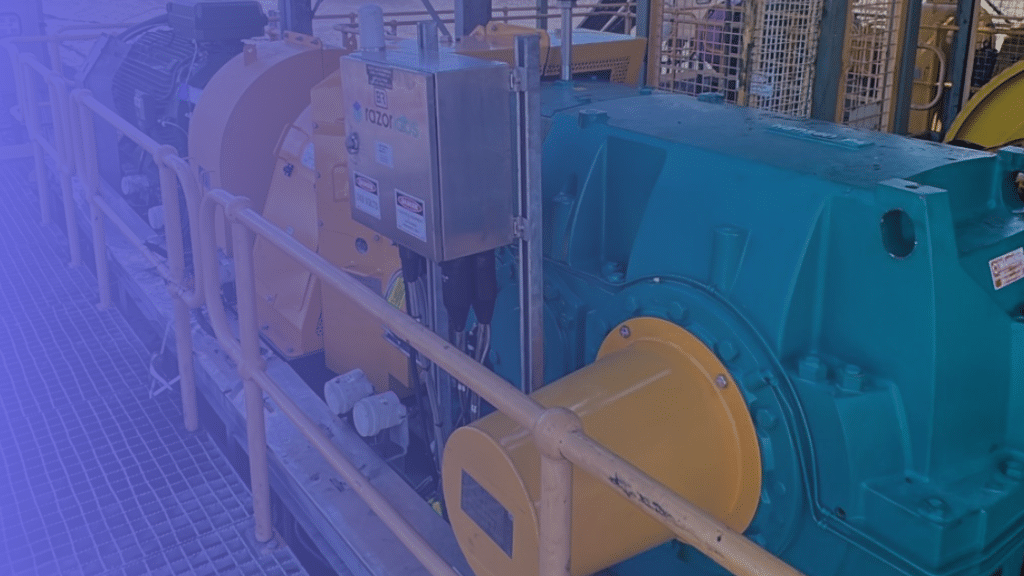

Estudio de caso: DataMind AI™ previene fallas en motores de cintas transportadoras detectando estrías ocultas en los rodamientos.

By Razor Labs 5 min read SHARE Overview At a large coal mining site, DataMind AI™ was deployed to monitor multiple conveyor drive motors – critical components in the site’s material handling process. Shortly after deployment, the system flagged early-stage deterioration in one of the motor bearings. While traditional monitoring tools recognized this as a […]

PODCAST: Razor Labs en The Northern Miner – Mantenimiento predictivo con fusión de sensores de IA

by Razor Labs 4 min read SHARE In this episode of the Northern Miner Podcast, Michael Zolotov, CTO & Co-Founder of Razor Labs, joins host Adrian Pocobelli to discuss how AI Sensor Fusion is redefining predictive maintenance in mining. Learn how Razor Labs’ flagship product, DataMind AI, combines data from vibration sensors, oil analysis, camera feeds, […]

Lanzamiento de DataMind AI™ 4.1: Desbloqueando un mantenimiento predictivo más rápido e inteligente

By Razor Labs 5 min read SHARE Razor Labs, a leader in AI-driven predictive maintenance, proudly announces the release of DataMind AI™ Version 4.1 — a major update that brings groundbreaking innovations to real-time decision-making, diagnostic accuracy, and maintenance workflows across mining and heavy industry. DataMind AI™ 4.1 is engineered to meet the growing operational […]

Extracto de caso de estudio: Detección temprana de fallas en rodamientos en una bomba crítica usando DataMind AI™

By Razor Labs 5 min read SHARE At a large power plant, a critical high-performance pump motor began showing subtle vibration behavior that conventional systems failed to detect. DataMind AI™ identified the early signs of bearing degradation through advanced real-time analysis – before any alarms were triggered or damage occurred. The insights enabled the team […]

Understanding MTBF in Maintenance: Its Meaning and Role in Predictive Strategies

Predictive maintenance is equipment maintenance that is based on the ability to predict equipment failures, by leveraging real-time data from various sensors and applying AI algorithms.

Extracto de caso de estudio: La IA visual detecta el desgaste del revestimiento de la trituradora y previene riesgos de producción

By Razor Labs 5 min read SHARE Discover how DataMind AI™ Visual AI Monitoring helped a ferroalloy site identify subtle material flow anomalies after the jaw crusher – well before visible failure signs appeared. Through continuous monitoring of size distribution trends, the system provided early, actionable insights that enabled proactive maintenance during planned downtime […]