Análisis de Vibraciones en Minería: Por Qué Superar los Métodos Tradicionales es Importante

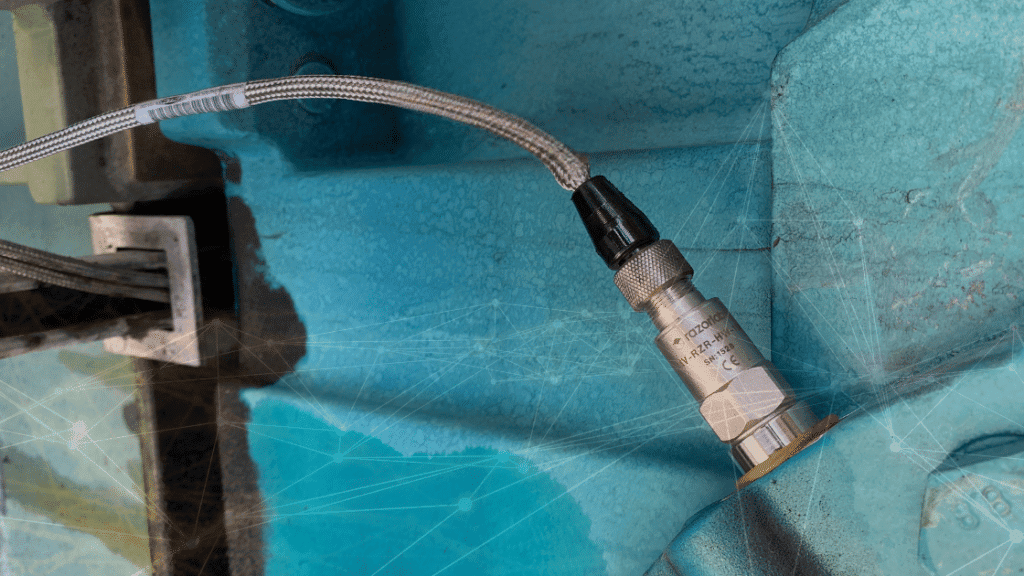

Predictive maintenance is equipment maintenance that is based on the ability to predict equipment failures, by leveraging real-time data from various sensors and applying AI algorithms.

Understanding MTBF in Maintenance: Its Meaning and Role in Predictive Strategies

Predictive maintenance is equipment maintenance that is based on the ability to predict equipment failures, by leveraging real-time data from various sensors and applying AI algorithms.

Razor Labs en el Consorcio Trust.AI: Pioneros en la Investigación sobre Toma de Decisiones con IA

Predictive maintenance is equipment maintenance that is based on the ability to predict equipment failures, by leveraging real-time data from various sensors and applying AI algorithms.

Transformando la Confiabilidad del Equipo Minero con Mantenimiento Predictivo

Predictive maintenance is equipment maintenance that is based on the ability to predict equipment failures, by leveraging real-time data from various sensors and applying AI algorithms.

Maximizando el Éxito del Monitoreo de Condición: Cinco Factores Clave a Considerar

When appropriately implemented, Condition Monitoring systems can have an immense positive impact on mining site operations. These are five key things to consider when introducing condition monitoring to ensure these programs succeed in providing value for mining sites.

Cuantificando el Impacto de DataMind AI™ en las Operaciones de un Sitio Minero

By Razor Labs 2 min read SHARE The move towards data-driven strategies in industrial maintenance marks a significant evolution in approaching equipment reliability and operational efficiency. Our team of experts has collected data from several selected sites where DataMind AI™ was deployed at the beginning of 2023. This blog post summarizes the average impact of […]

Estudio de caso: La principal minera de oro reduce el tiempo de inactividad no programado de los trituradores con DataMind AI

By Razor Labs 5 min read Download PDF SHARE The challenge The customer faced significant reliability challenges related to the site’s crushing circuit. The site experienced an average annual downtime of 250 hours. The financial impact of this unscheduled downtime and the associated lost throughput was estimated at $22,000/hour. The recurring failures resulted in increased […]