April 1, 2024

Advanced AI Sensor Fusion for Integrated Pumps Condition and Performance Monitoring

Pumps are indispensable in various heavy industrial applications for moving, extracting, and transferring fluids and slurries. Pump failures can lead to significant operational setbacks, including delays, production losses, and elevated maintenance expenses. Such downtimes can interrupt the entire process flow, affecting productivity and profitability.

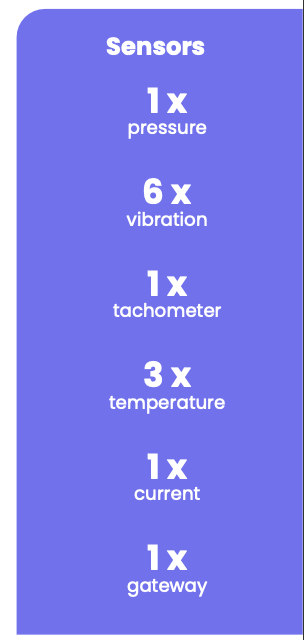

Thus, diligent maintenance, monitoring, and proactive management of pumps are crucial to maintain seamless operations and avert costly disruptions. DataMind AI by Razor Labs offers a comprehensive automated solution for simultaneous condition and performance monitoring of pumps.

Limitations of Existing Monitoring Approaches

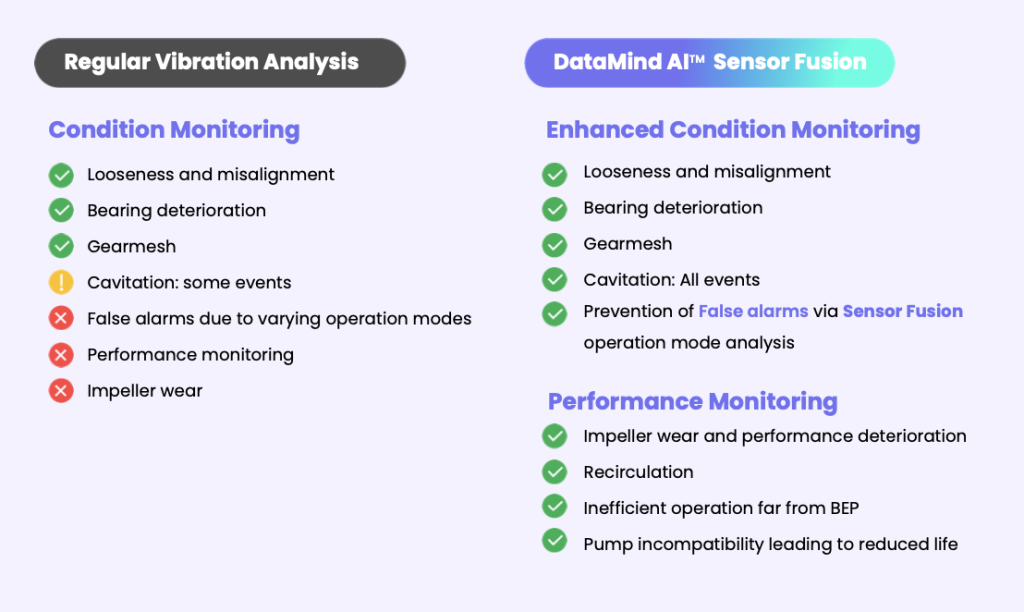

Current monitoring solutions fall into two main categories. The first includes vibration-based solutions that only detect a narrow range of issues like bearing wear and looseness, missing a broad spectrum of performance-related problems. For example, a pump might operate with a severely worn impeller, failing to deliver adequate pressure and severely impairing the industrial process. Yet, these systems would completely miss such a scenario.

The second category comprises PLC and SCADA systems that might alert on pressure issues. However, due to their simplistic threshold-based logic that doesn’t account for the pump’s variable load and operational changes, these systems either inundate the operator with false alarms or provide delayed alerts. The process might have already been tripped when the alert was received, affecting the entire site’s throughput.

Pump Condition Monitoring

vs. Pump Performance Monitoring

Condition Monitoring and Performance Monitoring serve as two integral components in the management and upkeep of pump systems.

Condition Monitoring concentrates on critical elements such as the motor, gearbox, and bearings, identifying standard failure modes like gear mesh errors, looseness, misalignment, and bearing degradation. In contrast, Performance Monitoring examines the pump’s operational effectiveness and ability to generate pressure by assessing flow rate, pressure, energy consumption, and conformity to the designated pump performance curve.

While Condition Monitoring seeks to prevent unforeseen failures by detecting early indicators of component wear, Performance Monitoring ensures the pump’s continuous optimal performance and efficiency throughout its operational lifespan.

DataMind AITM is the only predictive maintenance platform equipped with Pump Condition and Performance Monitoring capabilities. This integrated approach grants industrial operations deep visibility into their pump systems, enabling proactive maintenance, superior performance, and heightened reliability.