December 22, 2022

Although the potential is immense, studies show that most Predictive Maintenance programs fail to drive real value for mining companies.

In this blog, I will discuss three common myths about predictive maintenance and how mining companies can leverage AI sensor fusion to transform their predictive maintenance programs into value drivers.

Myth 1. The data collected by the mining companies can be easily used for Predictive Maintenance

Myth 2. Models that predict failures give (enough) value.

Myth 3. Deploying sensors is enough for Predictive Maintenance.

Myth 1. The Big Data miners collect can be easily leveraged for Predictive Maintenance.

Big Data vs. the Right Data

The first common misconception is that the big data that miners collect can be easily leveraged for predictive maintenance. Unfortunately, the reality is much more complex.

The existing information is mainly based on PLC Tags that are stored historically. These are hundreds of gigabytes of data, not fully relevant to perform predictive maintenance properly.

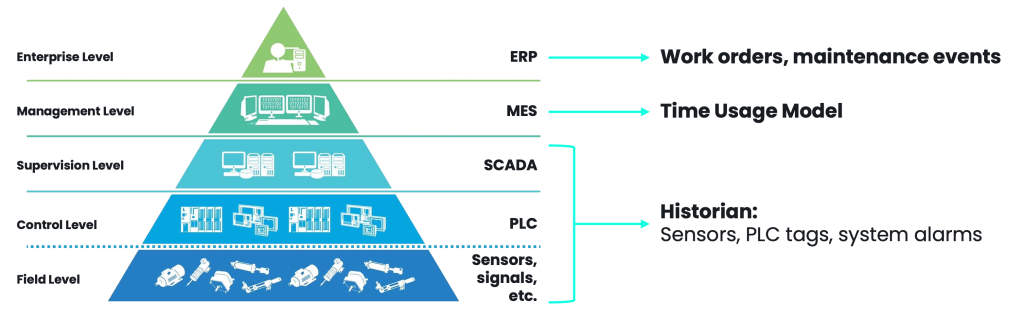

Let’s take a look at the automation pyramid below.

The Automation Pyramid

The automation pyramid shows all the organization’s data sources and information layers. The main parts of the data come from the lower layers of the pyramid.

First and foremost, these are the sensors installed on the machines that measure temperatures, vibration, power, and so on, in addition to other values calculated by the PLC systems, the machine’s computers, and the alarms.

The upper layers of the pyramid contain additional data sources, like ERP and MES, which are the tags used to train predictive maintenance models. These tags tell the model whether the machine had malfunctioned, and if it did, what was the reason, how the machine functioned when it was new, or how it behaved just before the replacement. This is the information available in most mining companies today.

However, if we were to talk to field condition monitoring experts whose primary focus is increasing the machines’ reliability, they would say they use entirely different data. Yes, they will refer to the Historian’s data mentioned above, but they will treat it as a secondary data type where predictive maintenance is concerned.

Data Sources Used by the Mining Condition Monitoring Experts

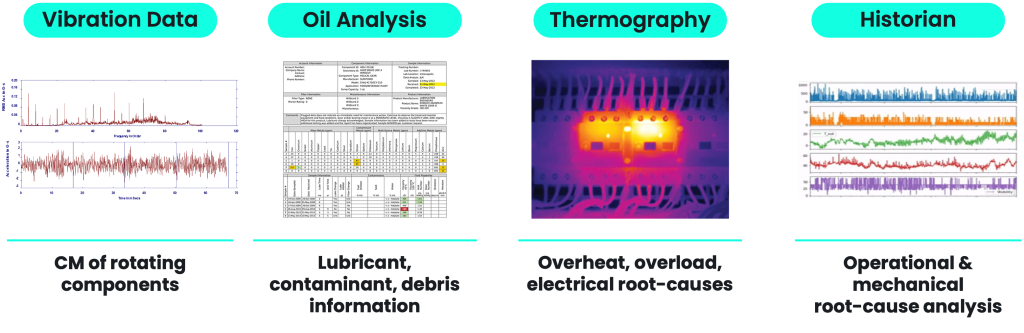

These are the data sources they would look at first:

- Vibration – Data collected from the vibration sensors gives us an excellent diagnosis of the various components and the ability to know which of the rotating parts is not in optimal health.

- Oil – The field ConMon teams will also focus on the oil analysis, which gives us knowledge about impurities in the oil, about debris in the oil, and so on

- Thermography – They will also look at the thermography reading obtained via temperature gauges, measuring overheat, overload, and various electrical problems.

- And finally, they will mention the historian data, but it will be, as we said, quite secondary to all other sources of data.

As you can see, there is a very large discrepancy between the information that experts in the field use for condition monitoring and the information collected by predictive maintenance solutions that are limited to the telemetry of the machines.

Performing condition monitoring only based on historical data is equivalent to asking a physician to diagnose a patient based on the data collected from the Apple watch. To properly diagnose a patient, the physician will order lab tests, CT/MRI scans, and many other check-ups to get a comprehensive picture of the patient’s health state.

To properly diagnose the machines’ health and execute predictive maintenance programs, in-depth data collected from various sources is mandatory.

In my next blog post, I will discuss the 2nd most common predictive maintenance myth – “Models that predict failures provide (enough) value.” Stay tuned