We got you covered

All your Predictive Maintenance requirements in a single out-of-the-box solution

Hardware

Sensors for a full 24/7 site

equipment coverage

DataMind AI™ Platform

Failure root cause analysis & clear

prescriptive actions

SME Support

Provided by the top-notch

conditioning monitoring experts

Software

Powerful AI Sensor Fusion

Technology

SME Support

Provided by the top-notch

conditioning monitoring experts

DataMind AI™ Platform

Failure root cause analysis & clear

prescriptive actions

Hardware

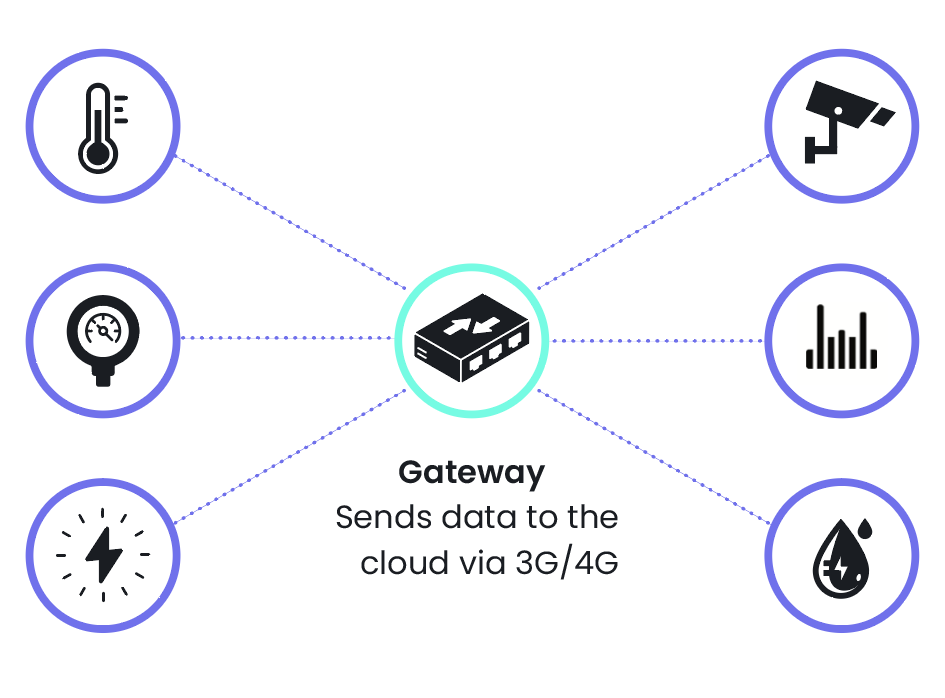

DataMind AI™ fuses data from a wide range of sensors to enable full equipment coverage.

- Seamless and quick IT-Free installation

- Supports complex variable-speed and variable- load equipment

- Leverages existing data sources, filling any sensor gaps for 24/7 monitoring

Superior Technology

DataMind AI™ is based on a powerful AI sensor fusion technology.

Collecting data from all sensors installed on machines, the neural network efficiently processes and learns from this vast information, identifying intricate patterns and correlations within the sensor data, and providing a comprehensive understanding of the machine’s health and behavior. No model calibration is required from the site team.

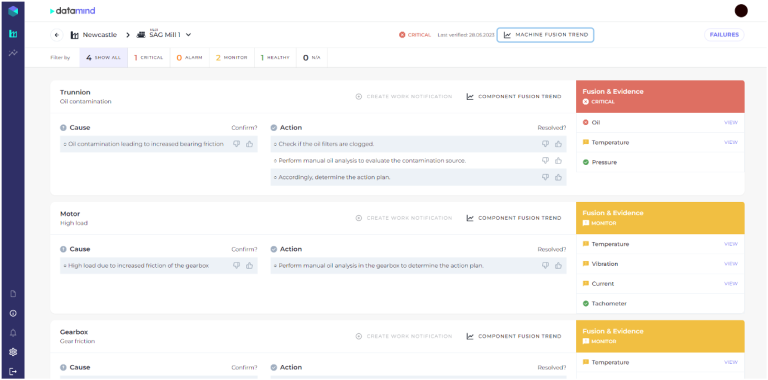

The platform comprises hundreds of combined years of domain expertise in mining equipment to indicate impending failures that require attention and uncover their potential root causes.

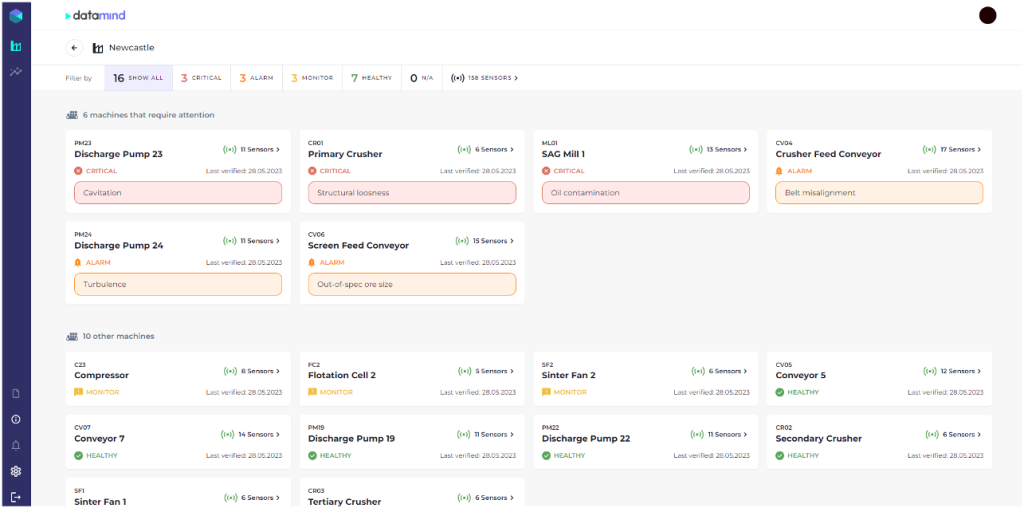

DataMind AI™ Platform

Complete online visibility of the site equipment

Sensor fusion for failure root cause analysis & prescriptive actions

Sensor fusion for failure root cause analysis & prescriptive actions

Complete online visibility of the site equipment

Extensive domain expertise

Our team of seasoned and licensed condition-monitoring experts brings a wealth of knowledge and experience to the table. Equipped with DataMind AI™ software platform, our SMEs are available for consultation and can provide in-depth domain expertise to ensure the most accurate and actionable insights into the health of your machines. The site team can consult with our experts regarding insights picked by the data models, the rationale behind specific diagnoses and prescriptive actions.

This collaborative approach guarantees comprehensive and well-informed decision-making processes for maintaining optimal machine performance.

Comprehensive sensor offering

DataMind AI™ fuses data from a wide range of sensors to enable full equipment and failure mode coverage.

Temperature

Overheat / overload

and failure severity estimation

Pressure

Pump/ fan performance

and efficiency monitoring

Current

Equipment overload

and operation modes

CCTV Camera

Material and equipment visual monitoring

and belt drift issues

Vibration

Condition monitoring

of rotating components

Oil

Oil contamination

and mechanical wear

DataMind AI™ at a glance

Conveyors

> 1000 prevented yearly downtime hours>1MT additional throughput

Stockyard

Crushers

>100 prevented yearly downtime hours

>25 prevented blockages per year

Mills

Monitored equipment

- Conveyors

- Reclaimers

- Stackers

- Ship loaders

- Crushers

- Heat exchangers

- Compressors

- Screens

- Sifters

- HPGRs

- Mills

- Flotation cells

- Pumps

- Filters

- Thickeners

- Kilns

- Furnaces

- Rolling mills

- Rollers

- Fans