Case Study Snippet: Visual AI Detects Crusher Liner Wear and Prevents Production Risks

April 28, 2025

By Razor Labs

5 min read

SHARE

April 28, 2025

Discover how DataMind AI™ Visual AI Monitoring helped a ferroalloy site identify subtle material flow anomalies after the jaw crusher – well before visible failure signs appeared.

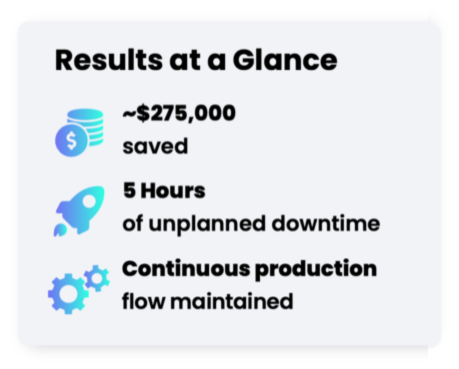

Through continuous monitoring of size distribution trends, the system provided early, actionable insights that enabled proactive maintenance during planned downtime – minimizing production risks and maximizing operational efficiency.

Conclusion

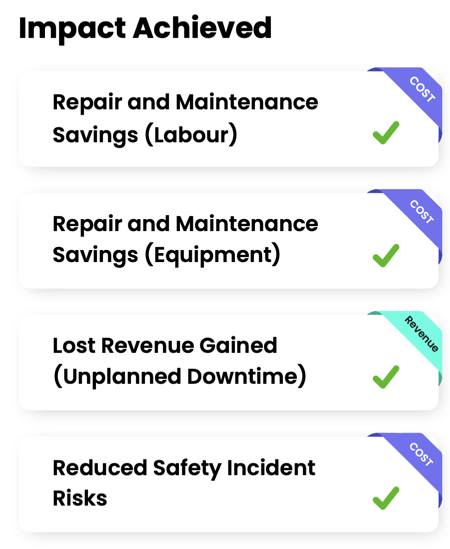

This case study illustrates how AI-powered visual analysis goes beyond traditional inspections – helping teams detect early signs of wear, optimize maintenance timing, and protect critical production assets.

Fill in the form to read an entire case study

SHARE