Case Study: DataMind AI™ Detects Gear Friction in Compressor Gearbox, Preventing Catastrophic Failure

September 15, 2025

Overview

DataMind AI™ was deployed at a vanadium mining site to monitor fixed rotating assets across production-critical systems. Among these assets was a key compressor, one of the most essential machines on site.

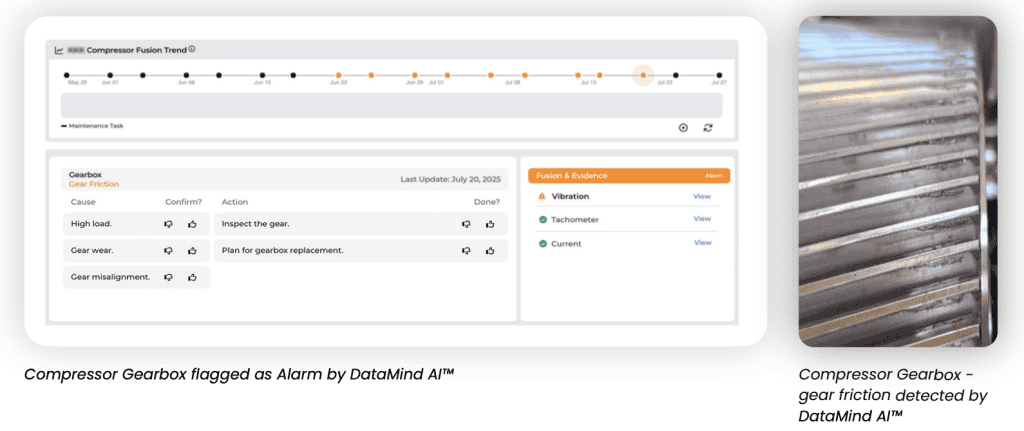

In mid-June 2025, DataMind AI™ flagged an Alarm on the compressor’s gearbox, identifying increasing vibration patterns associated with gear friction. Traditional inspection and condition-based monitoring had not detected this issue.

DataMind AI™ detected early signs of failure in the critical gearbox by identifying spectral signatures pointing to mechanical degradation – including localized gear wear, potential misalignment, and load-induced friction.

Following the system’s alert, the maintenance team initiated an inspection and opened the gearbox. They confirmed visible wear on one side of the bull gear – matching DataMind AI™’s predictions exactly.

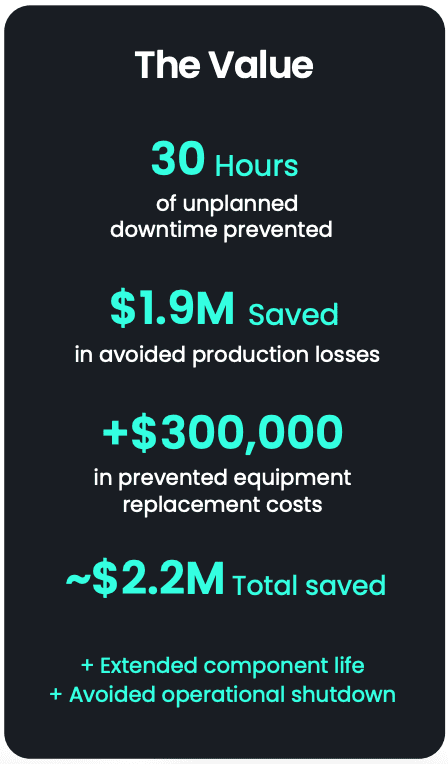

Left unresolved, this failure could have escalated into a full breakdown, with equipment replacement alone valued at over $300,000, and an additional $1.9M in lost production.

Envelope Demodulation and AI Sensor Fusion Prove Critical in Failure Detection

The compressor operates under a range of load and speed conditions, which often hide early signs of mechanical wear. Traditional vibration monitoring struggles to distinguish between operational variability and true degradation.

DataMind AI™ overcame this challenge using operation mode filtering (applying the motor current and the tachometer), followed envelope demodulation. This combination allowed the system to isolate deterioration patterns during nominal operation and provided a clear diagnostic signal.

Through this approach, the system was able to:

- Detect early signs of gear surface damage

- Eliminate false positives caused by fluctuating load conditions

- Accurately pinpoint gear mesh degradation

Detection

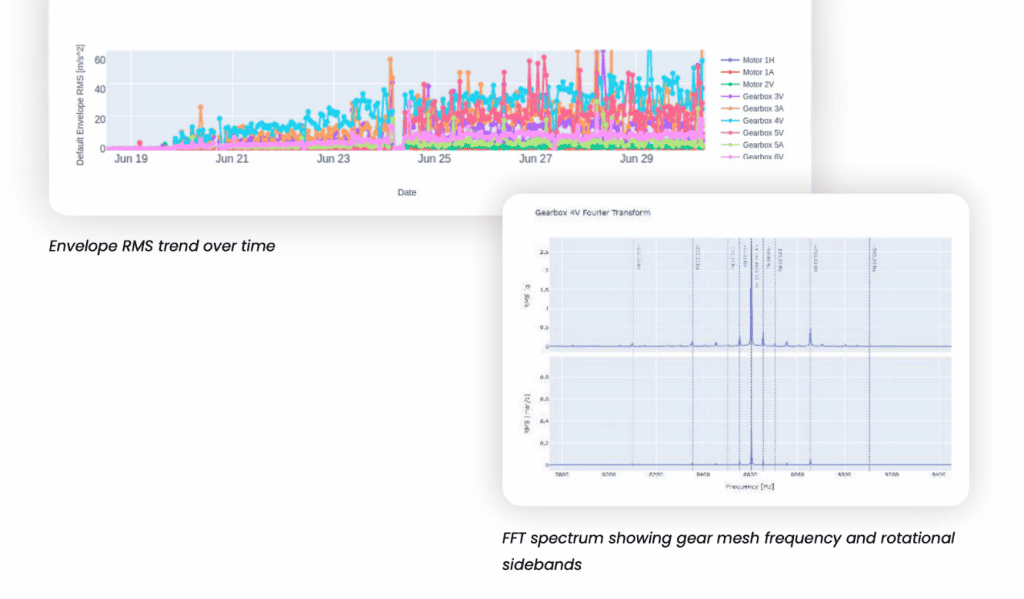

Between mid-June and early July, following a gearbox replacement, DataMind AI™ detected a continuous rise in envelope demodulation levels across multiple gearbox sensors. This trend clearly indicated progressive mechanical deterioration, well before any functional symptoms appeared.

Complementing the trend analysis, frequency-domain diagnostics revealed a sharp peak at 8605 Hz, corresponding to the gear mesh frequency. Distinct sidebands were observed at 50 Hz and 252 Hz, matching the known rotational speeds of the gearbox shafts. These spectral features are strong indicators of gear friction and misalignment under load – consistent with developing gear surface damage.

Vibration trend analysis shows increased levels:

Alert Received

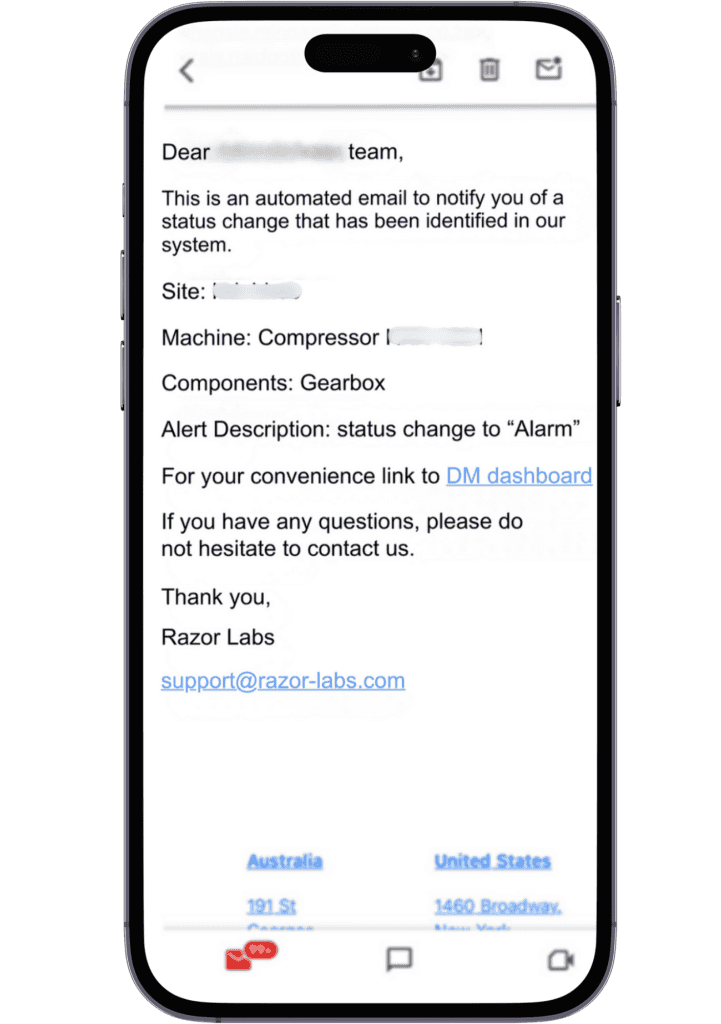

Following the trend escalation, DataMind AI issued an alert and recommended inspection of the gearbox.

Given the criticality of the machine at site, Razor Labs’ condition monitoring specialists met with the site team to discuss the diagnosis, address their questions, and ensure they have all the information needed to act optimally in this case.

Resolution & Inspection

The site reallocated the tasks in the next planned shutdown to inspect the gearbox. Upon opening it, technicians discovered uneven gear wear on the bull gear – precisely as predicted by DataMind AI™. The gear was realigned and repaired during the planned intervention.

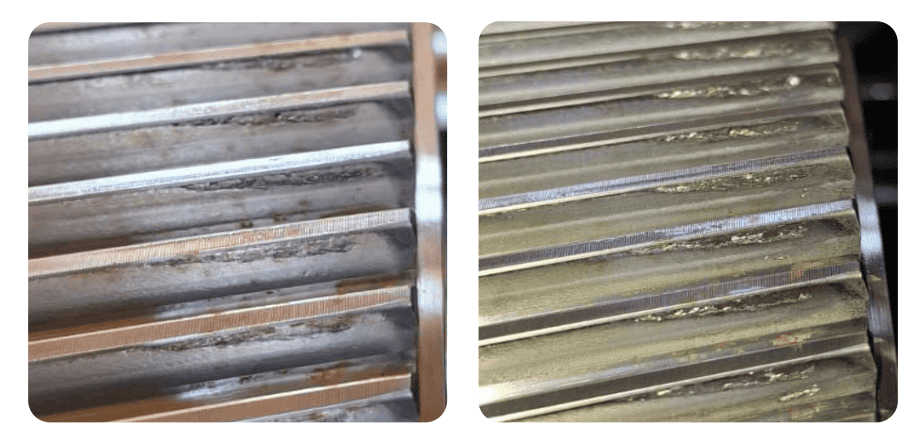

Inspection photos confirmed localized wear patterns consistent with progressive frictional fatigue. The early alert enabled the maintenance team to act proactively, complete the repair without unplanned downtime, and avoid a costly failure

Gear wear visible on one side of the bull gear, indicating friction-related degradation

Conclusion

This case highlights DataMind AI™’s ability to uncover hidden mechanical degradation long before traditional monitoring methods can detect it.

By fusing vibration and operational data for operation mode filtering and envelope demodulation, the system delivered precise, actionable diagnostics – enabling the maintenance team to act early, avoid unplanned downtime, and protect one of the site’s most critical assets: the process compressor.

As a result, the team avoided a potential $300,000 gearbox replacement and over $1.9 million in production losses, with total savings exceeding $2.2 million.