Case Study: Combustion Imbalance Detected by DataMind AI in Komatsu 930E

February 20, 2026

Overview

DataMind AI™ for Mobile Fleet was deployed across a large mining operation to monitor its haul truck fleet, including Komatsu 930E units, uncovering mechanical faults that OEM systems and alert overload had failed to detect. The failure in this case originated within the Engine Air & Exhaust system.

In this case, DataMind AI™ uncovered abnormal combustion behavior across three engine cylinders. Despite recent mechanical interventions (injector replacements and a cylinder head swap), exhaust gas temperatures remained unstable.

Importantly, cylinder 13 displayed abnormally low and erratic exhaust temperatures – a clear sign of possible injector malfunction or incomplete combustion, yet it had gone unnoticed.

The team had already performed interventions on cylinders 6 and 7 without realizing the issue

extended further, as no OEM alerts had flagged cylinder 13.

Thanks to early detection and built-in mechanical reasoning, DataMind AI™ helped the team understand the full scope of the failure – enabling early, informed intervention that prevented unnecessary damage and protected engine health.

DataMind AI Diagnostic Methology

Built-in Mechanical Knowledge

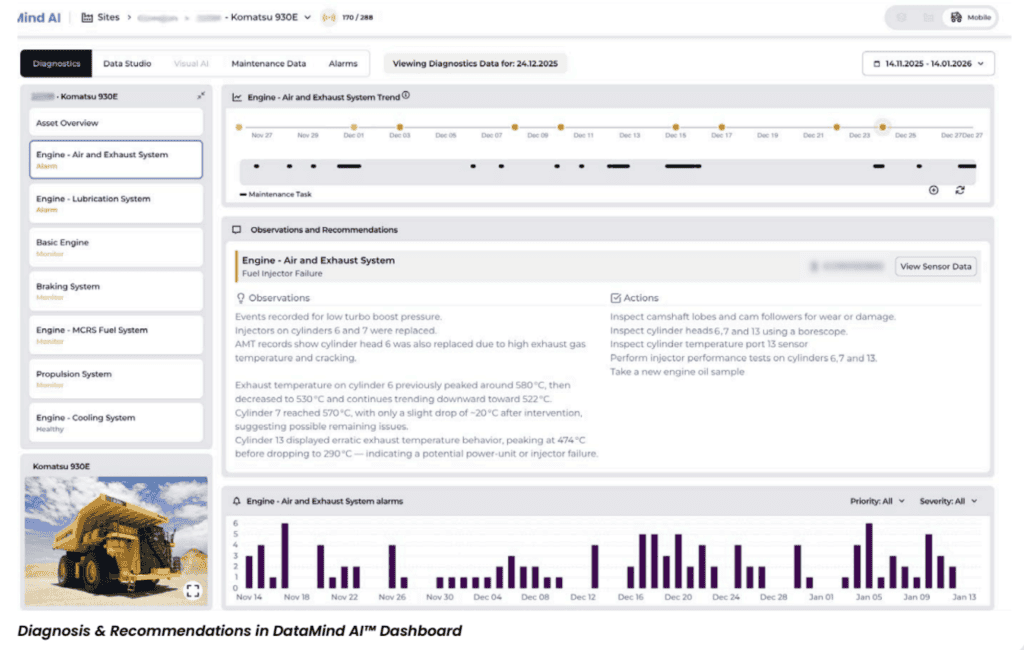

Using sensor fusion and embedded mechanical reasoning, DataMind AI™ analyzed:

Air & Exhaust system signals: exhaust gas temperatures, exhaust gas temperature differences, boost pressure, air filter restriction

Operational signals: engine load, throttle position, RPM, payload

Maintenance records: injector replacements on Cylinders 6 and 7

- Oil sampling data: elevated soot levels

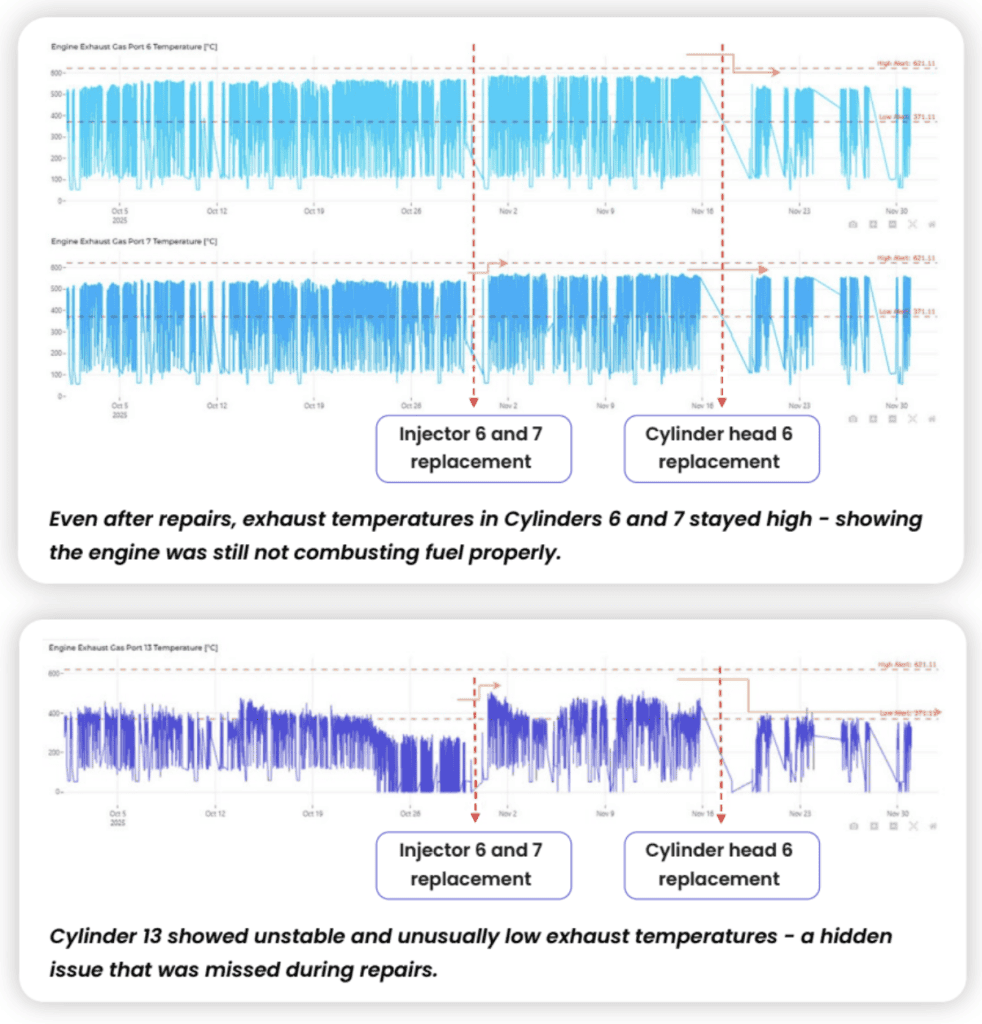

The system detected combustion irregularities across Cylinders 6, 7, and 13 – including unresolving thermal behavior and unexpected temperature drops, especially in Cylinder 13.

Diagnosis

- Cylinder 6: Peaked at 580°C prior to cylinder head replacement; decreased to ~530°C

- Cylinder 7: Reached 570°C; showed minimal improvement post-repair

- Even after repairs, exhaust temperatures in cylinders 6 and 7 stayed high – showing the engine was still not combusting fuel properly

- Cylinder 13: Showed abnormally low and unstable exhaust temperatures, dropping from ~474°C to ~370°C

These thermal behaviors suggested incomplete combustion and injector malfunction. Cylinder 13 had not been monitored by the site team, and yet showed the clearest sign of deeper issues.

Recommended Actions

- Injector performance tests on cylinders 6, 7, and 13

- Borescope inspection of cylinder heads 6, 7, and 13

- Inspect camshaft lobes and followers

- Check cylinder 13 temperature sensor accuracy

- Conduct new engine oil sampling to assess contamination

Action & Follow-Up

Based on DataMind AI™ recommendations, Cylinder 13 was flagged for replacement.

After the intervention, exhaust temperatures stabilized, validating the diagnosis and resolving the combustion imbalance.

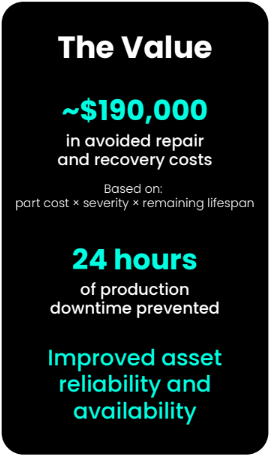

Results

- Zero unplanned downtime

- Early detection of combustion imbalance, before damage occurred

- Continuous production maintained without engine disruption

- Avoided unnecessary repairs by surfacing hidden issues

- Improved team confidence and diagnostic accuracy

Summary

This case highlights how DataMind AI™ delivers early, high-confidence fault detection that traditional OEM

systems miss.

By continuously analyzing live sensor data and correlating it with mechanical behavior, the platform uncovered a hidden combustion fault, before any alerts were triggered.

The result: $190,000 in avoided repairs, 20 hours of production saved, and zero unplanned downtime.