Case Study: DataMind AI™ Detects Early Fuel Injector Degradation in CAT 793D Haul Truck

December 18, 2025

Overview

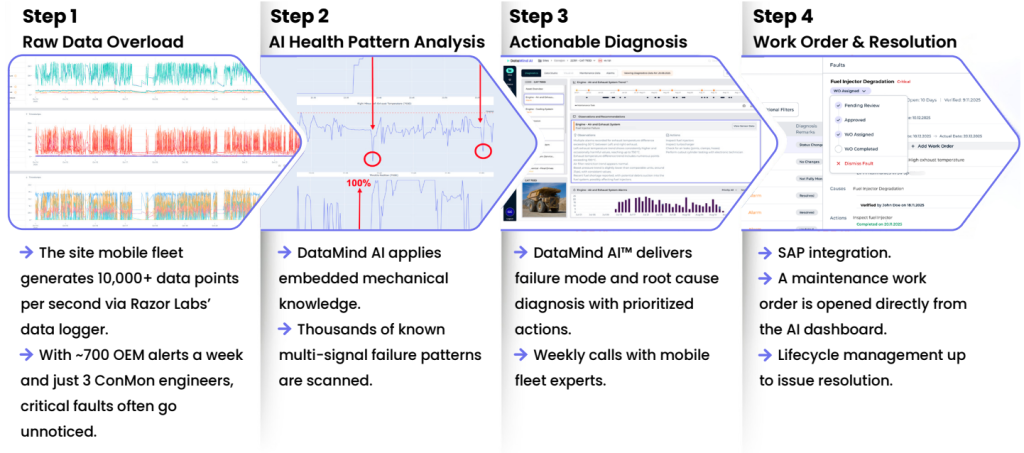

DataMind AI™ for Mobile Fleet was deployed at a large coal mining operation to continuously monitor heavy mobile equipment in real time and deliver actionable health insights across the fleet.

During routine operation, the fleet generated a very high volume of OEM alarms. In a single week, more than 650 alerts were raised across the site, including over 41 critical alerts on one CAT 793D haul truck.

This alarm saturation reduced the effectiveness of the Reliability and Condition Monitoring teams. Significant time was spent investigating false and low-value alerts, making it difficult to prioritise real mechanical risk. As a result, early-stage but high impact deterioration could easily be missed.

By applying AI sensor fusion with embedded mechanical knowledge, DataMind AI™ identified a true failure pattern hidden in the noise. The system detected early fuel injector degradation, causing combustion imbalance under high-load acceleration.

This enabled proactive intervention weeks before a breakdown, preventing multiple shifts of downtime and ensuring continuous production and fleet availability.

DataMind AI Diagnostic Methology

AI-Driven Diagnostics in Action

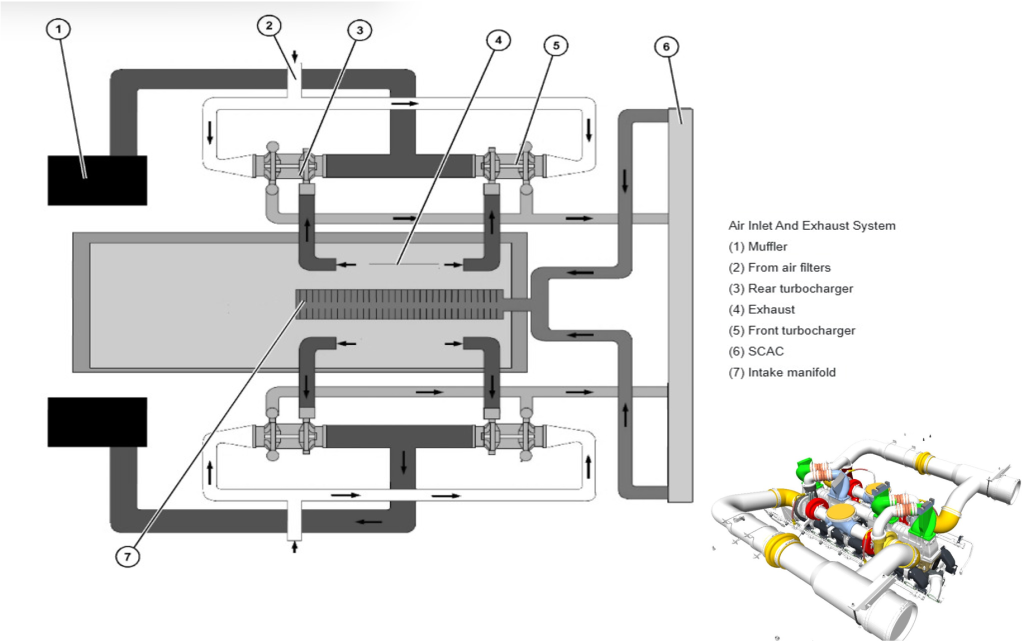

The platform combines sensor fusion with embedded mechanical reasoning to analyze complex operational behavior in real time.

In this case, DataMind AI™ analyzed:

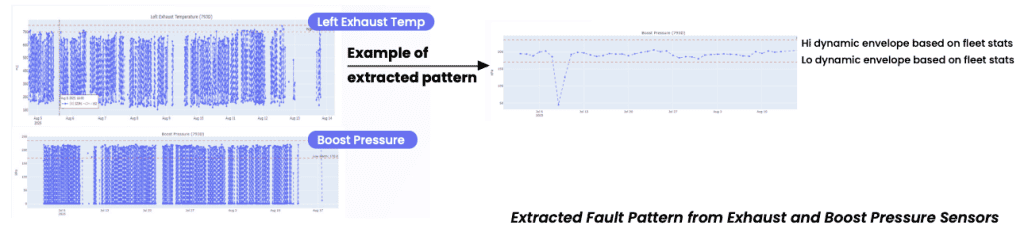

- Air & Exhaust system sensors: air filter, boost pressure, left/right exhaust temperatures, and exhaust temperature delta (∆T)

- Operational sensors: throttle position, payload, engine speed and load, ground speed.

- Oil samples.

- Maintenance work orders.

By integrating these data sources, the model ruled out airflow restrictions and turbocharger malfunction, identifying a combustion imbalance pattern consistent with early-stage fuel injector degradation.

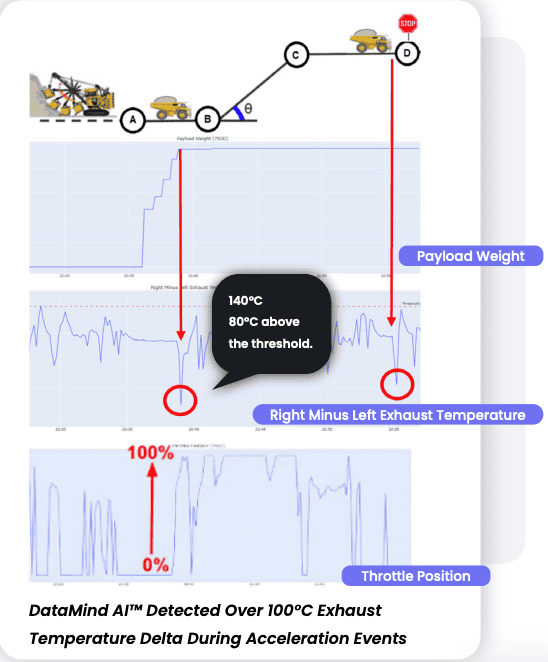

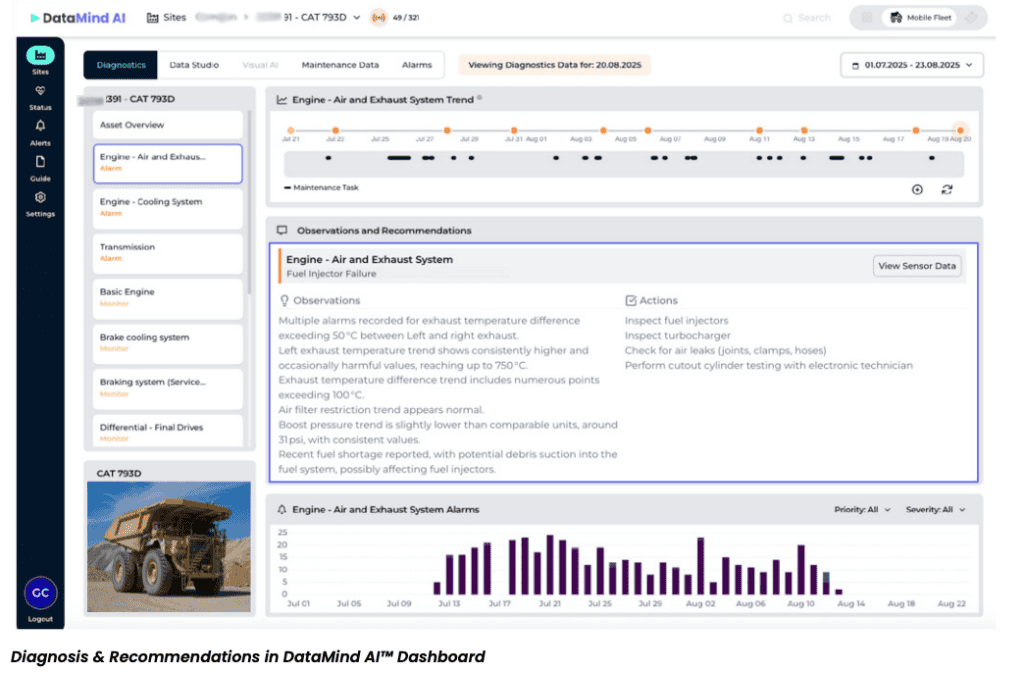

Diagnosis

- DataMind AI™ detected a consistent exhaust temperature delta exceeding 100°C between the left and right banks during full-load acceleration – a clear sign of combustion imbalance.

- These spikes aligned with rapid throttle jumps from 0% to 100% under maximum payload, indicating injector-related irregularities under stress.

- Left exhaust temperatures reached 750°C – still under OEM thresholds, but significantly above the fleet average.

- Boost pressure readings were lower than expected for the same load conditions, further supporting a

loss in combustion efficiency. - No OEM alerts or operator complaints were registered for this anomaly – underscoring the value of

AI-driven diagnostics. - Turbocharger faults and air leaks were ruled out via cross-sensor validation, narrowing the root cause

to early-stage fuel injector degradation.

Recommended Actions

- Perform fuel-injector inspection

- Run cylinder cutout test to isolate affected cylinder

- Inspect for air leaks: clamps, joints, hoses

- Evaluate turbocharger performance

Action & Follow-Up

- Following DataMind AI™ alert and diagnostic summary, the site scheduled inspection for the injector system.

- The data-driven recommendation supported a precise, proactive response – helping the team avoid reactive failure and maintain operational continuity.

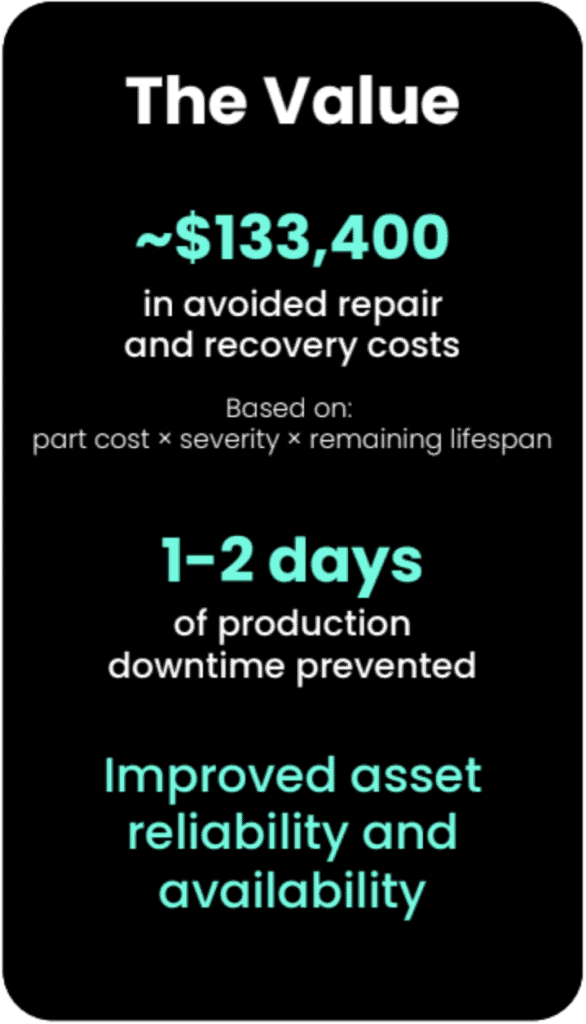

Results

- No unplanned downtime

- Fault identified early, before symptoms

- Enhanced confidence in DataMind AITM insight

- Planned inspection allowed better resource coordination

Summary

This case highlights how DataMind AI™ enables early, high-confidence fault detection in mission-critical mobile equipment.

By identifying hidden patterns that traditional systems miss – and translating them into clear root causes and

actions – the platform helps mining teams maintain uptime, reduce maintenance cost, and extend component life.