Case Study: DataMind AI™ Detects Lubrication Fault in Ventilation Fan

July 2, 2025

Overview

Razor Labs deployed DataMind AI™ to monitor critical rotating equipment at a major coal mining site with underground operations – including a key ventilation fan essential for maintaining airflow and ensuring safe working conditions below ground.

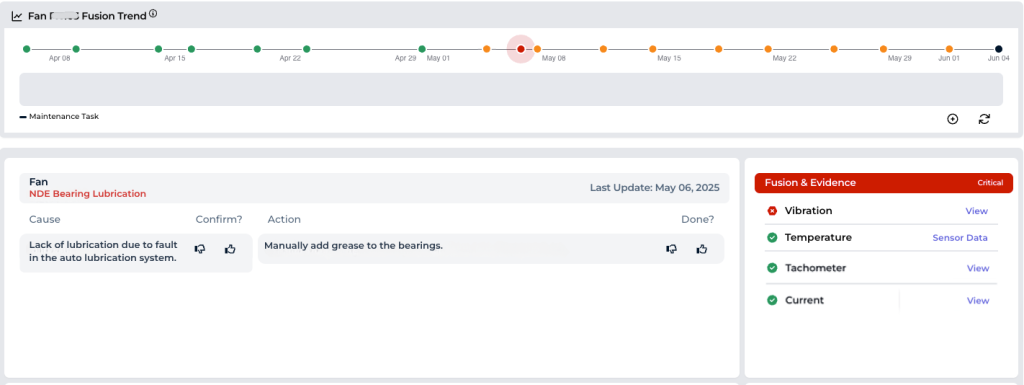

In May 2025, DataMind AI™ detected rising bearing friction through multi-sensor analysis, pinpointing lubrication failure as the root cause. The system initially classified the trend as an Alarm and later escalated it to Critical as the condition worsened. Through multi-sensor analysis, the system helped isolate the mechanical root cause: a progressive rise in

friction levels leading to lubrication failure.

The site team confirmed that the fan’s automated greasing system had malfunctioned – a jammed grease cartridge had prevented lubricant from reaching the bearings. This fault had gone undetected until DataMind AI™ flagged the trend. Based on these insights, the team manually re-greased the bearings and restored proper lubrication –

preventing premature bearing wear, unplanned downtime, and potential airflow disruption.

Fan flagged as Critical

Detection & Diagnosis

Sensor Fusion Analytics allowed DataMind AI™ to distinguish real mechanical changes from operational noise. The fan operates in fluctuating conditions – flow, pressure, and motor load – which often mask early signs of mechanical deterioration.

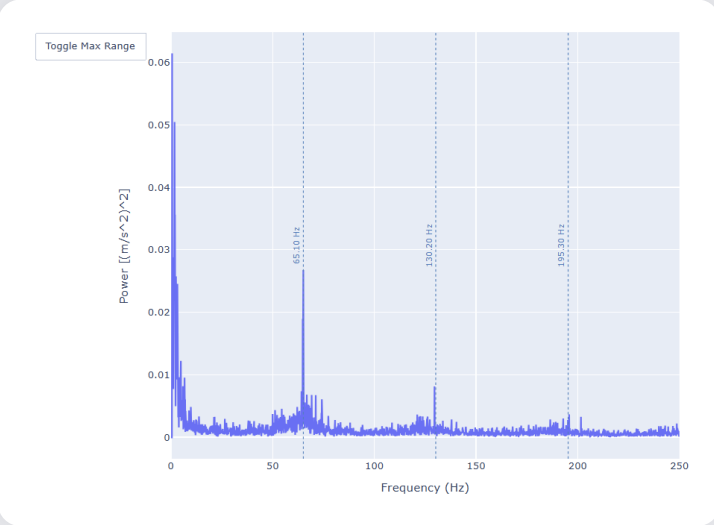

By synchronizing vibration, tacho, and motor current signals, along with advanced vibration analysis using envelope demodulation algorithms, the system confidently isolated the degradation pattern and identified its mechanical origin.

Key insights included:

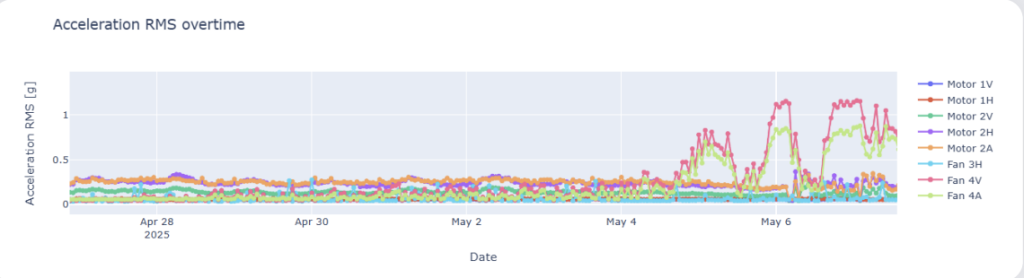

- Elevated high-frequency noise floor revealed early-stage friction buildup inside the bearing

- Acceleration RMS spikes aligned with changing operational load, confirming persistent stress

- Advanced envelope demodulation isolated subsurface mechanical impacts – identifying a lubrication-related fault pattern before surface damage escalated

Operational mode filtering reduces noise from load and speed variations, enabling clear visibility of the underlying deterioration trend.

Envelope demodulation analysis

Spectrum analysis of NDE bearing of the fan

Resolution

Following manual greasing, the system recorded a clear reduction in bearing vibration. This validated the diagnosis and eliminated the need for premature bearing replacement. The team avoided unscheduled shutdown, extended component life, and restored safe ventilation – a mission-critical function in underground mining.

Conclusion

This case demonstrates the unique value of DataMind AI™ in identifying hidden mechanical issues that standard inspections miss. By pinpointing the true root cause of friction-related degradation in the underground ventilation fan, the system enabled fast resolution and prevented costly disruption.