Case Study: Detecting bearing lubrication issue in a compressor with DataMind AI™

June 22, 2025

Overview

At a major coal mining site, DataMind AI™ was deployed to monitor critical equipment, including compressors essential for plant auxiliary operations. After the deployment, the system flagged one compressor’s drive-end bearing for abnormal vibration levels – well above those observed in identical units.

While traditional tools may have detected a generic fault, DataMind AI™ went further: using AI-driven diagnostics, it identified the underlying cause – abnormal friction likely resulting from lubrication issues. Rather than recommend immediate replacement, the system guided a structured troubleshooting process that avoided downtime and unnecessary intervention.

AI-Guided Diagnosis

- Friction Detected: DataMind AI™ identified a consistently elevated noise floor at high frequencies – an early sign of bearing friction. The pattern suggested a lubrication-related issue.

- Flow Integrity Verified: The system recommended checking grease flow paths. The site confirmed that inlet and purge ports were clear, ruling out blockage as the cause.

- Quantity Mismatch Identified: AI insights prompted a review of the applied grease volume. The team discovered only 20g had been used – well below the OEM-recommended 50g.

- Corrective Action Taken: After applying the correct amount, vibration levels dropped significantly – validating that lubrication was directly linked to the issue.

Detection & Comparative Analytics

In addition to identifying the local issue, DataMind AI™ compared performance across similar compressors:

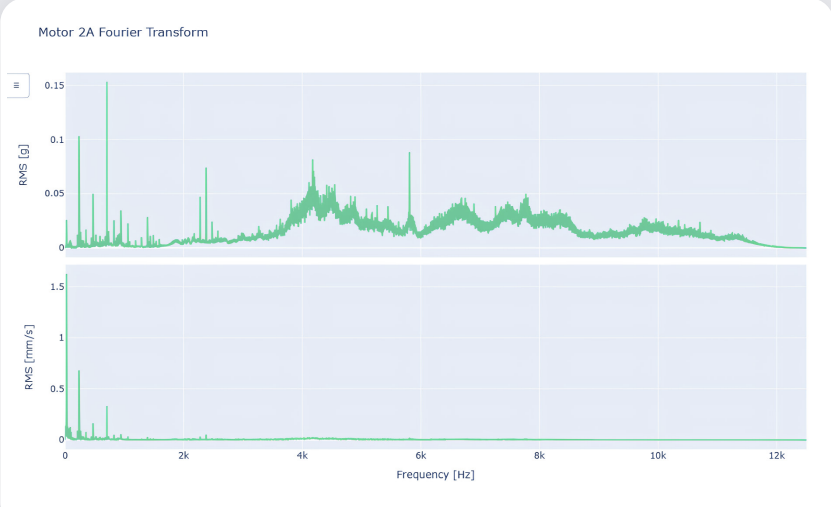

Spectrum Analysis: Revealed a raised noise floor consistent with internal friction.

Spectrum analysis with elevated noise floor

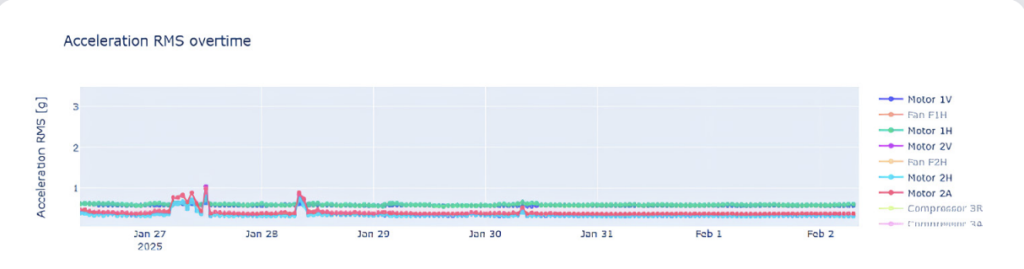

Comparative View: Compressor performance was significantly worse than peers under similar load

Affected compressor

Compared to unaffected compressor

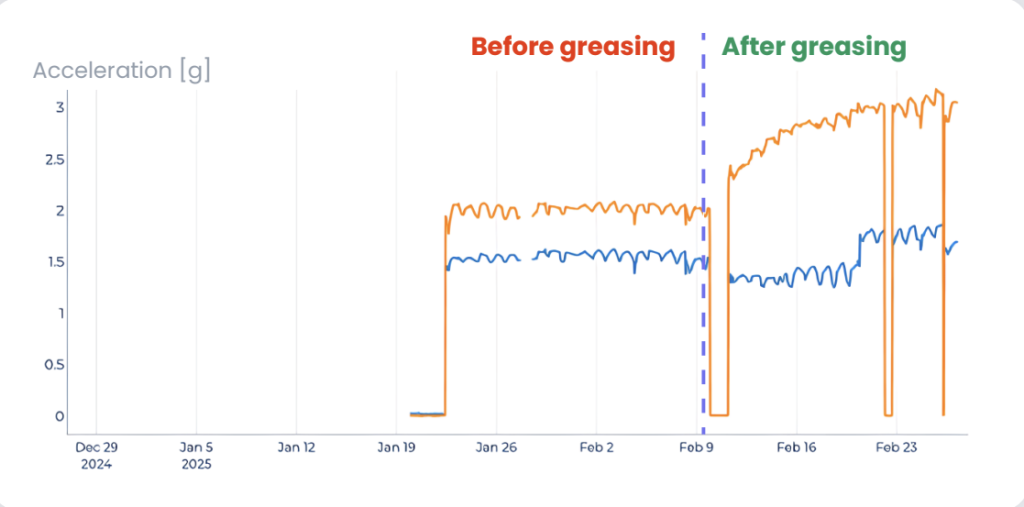

Greasing Event Correlation: Instead of decreasing, vibration levels actually increased after greasing – indicating that the applied grease quantity was potentially incorrect and inconsistent with the required specification.

Acceleration RMS trend

A comparison between the grease quantity recorded in the work order and the OEM recommendation revealed that only 20g of grease was applied on-site, whereas the OEM specifies 50g.

Resolution

Thanks to DataMind AI™, the site avoided premature replacement and optimized planned maintenance instead. The system’s layered diagnostics – leveraging its integration with work orders to compare actual greasing with required quantities – enabled DataMind AI™ to detect human error by cross-checking what was performed against what was needed. This enabled comprehensive root cause investigation.

The real-time feedback also aligned internal and external teams around the same data, helping the team stay coordinated while minimizing operational disruption.

Conclusion

DataMind AI™ provided more than just early alerts – it delivered structured, data-backed decision-making. By guiding the site through friction detection, root cause investigation, and corrective action, the system enabled smarter maintenance planning.

As a result, the site avoided 5 hours of unplanned downtime, saved approximately $140,000, and gained new clarity into compressor health – highlighting the power of AI to improve reliability, reduce cost, and drive smarter industrial performance.