Case Study: Radiator Blockage Detected by DataMind AI™ in CAT 793D

January 8, 2026

Overview

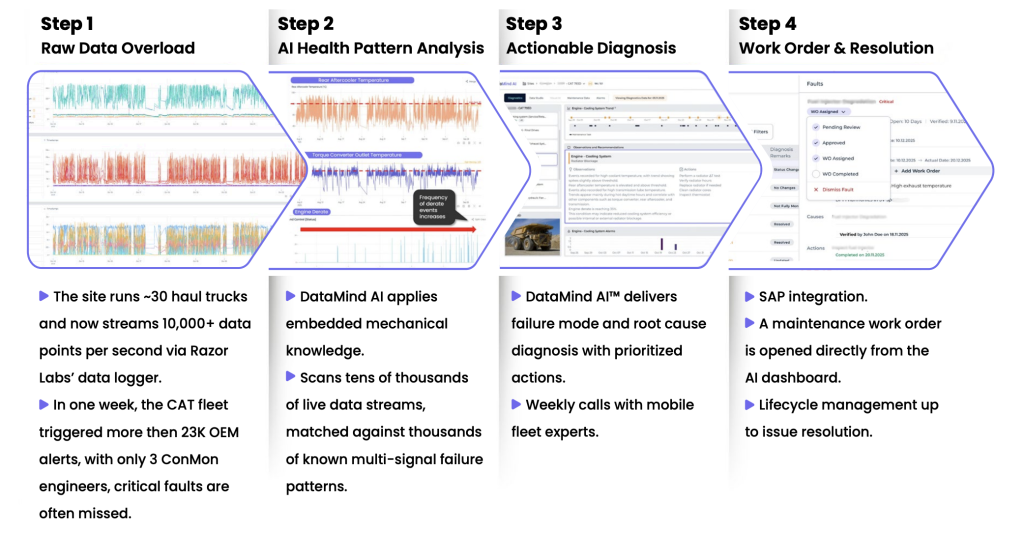

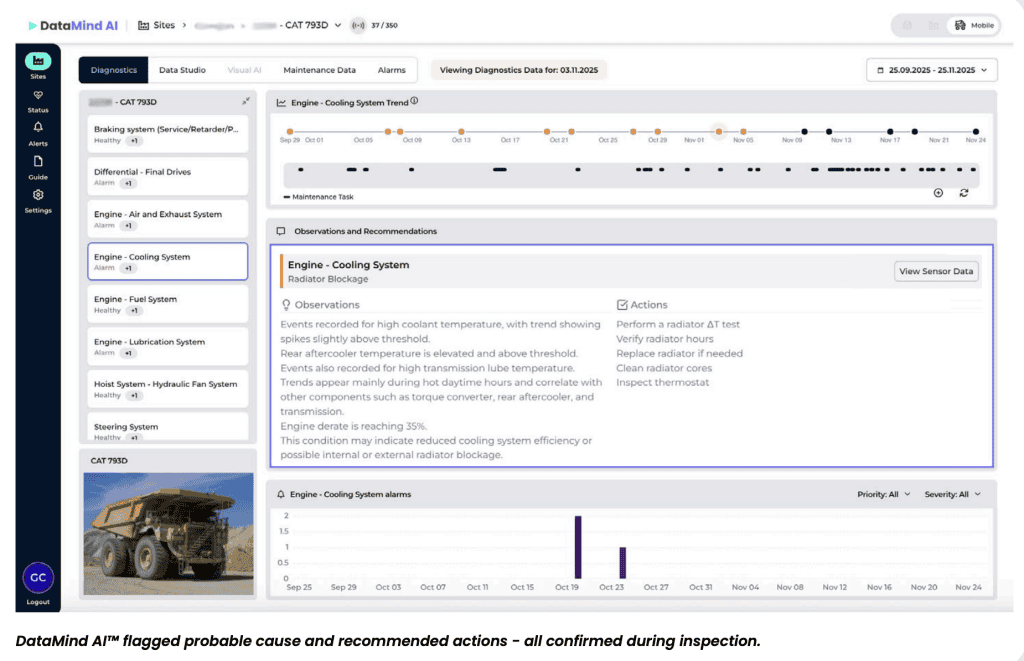

DataMind AI™ for Mobile Fleet was deployed at a large mining operation to monitor CAT 793D haul trucks and detect mechanical issues hidden beneath thousands of OEM alerts.

In a single week, the CAT fleet generated 23,132 OEM alerts, including 655 on one 793D haul truck making manual prioritization nearly impossible.

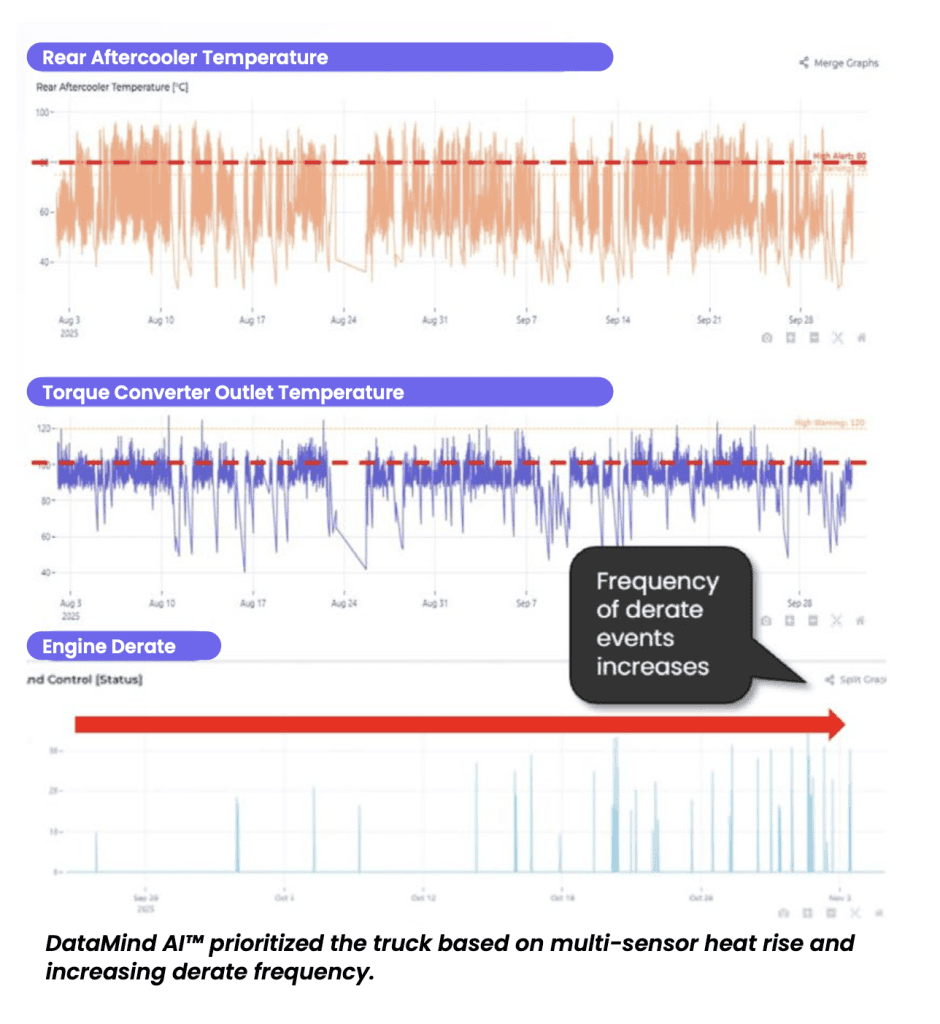

Despite the noise, DataMind AI™ pinpointed a real mechanical threat within the engine cooling system: a developing radiator blockage. This was indicated by rising temperatures across multiple cooling components and a growing frequency of engine derate events.

This early insight enabled the team to intervene before failure, protecting the engine and avoiding unplanned downtime.

DataMind AI Diagnostic Methology

Built-in Mechanical Knowledge

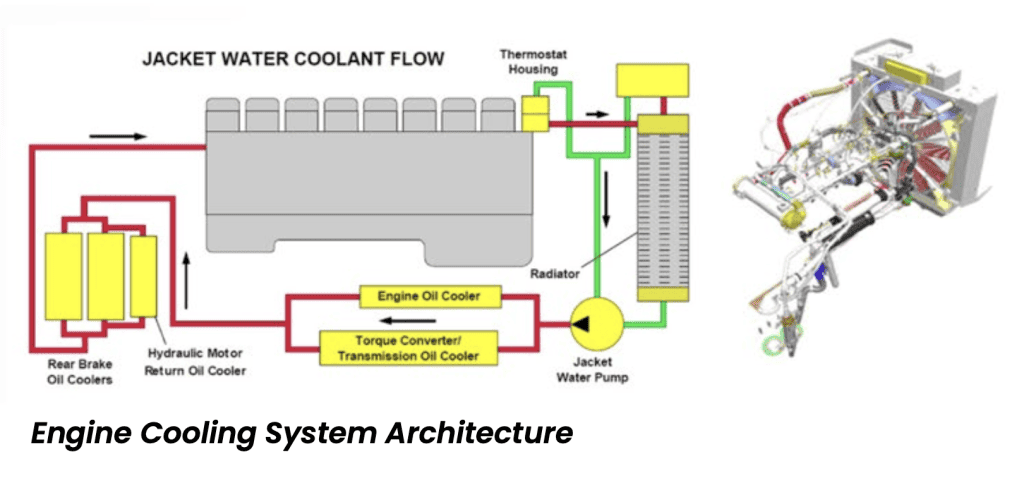

Using sensor fusion and embedded mechanical reasoning, DataMind AI™ analyzed:

- Cooling system sensors: fan speed, engine coolant temperature, aftercooler temperature, ambient air temperature, transmission lube temperature, torque converter temperature, and coolant level.

- Operational signals: payload, throttle position, engine load and speed, ground speed, and derate status.

- Additional inputs: coolant condition and recentmaintenance activity.

Diagnosis

- Simultaneous temperature rise across key cooling components.

- Linked to frequent derate events during loaded operation.

- Ruled out single-sensor error, confirming true mechanical degradation.

- Root cause identified: reduced cooling efficiency due to internal or external radiator blockage.

This pattern was detected across the torque converter, rear aftercooler, engine coolant, and transmission lube – especially during throttle spikes under load.

DataMind AI™ connected these signals to surface the true failure mode before breakdown.

Recommended Actions

- Perform radiator ∆T (temperature drop) test

- Check total radiator operating hours

- Inspect and clean radiator cores

- Evaluate thermostat for malfunction or blockage

- Plan radiator replacement if degradation is confirmed

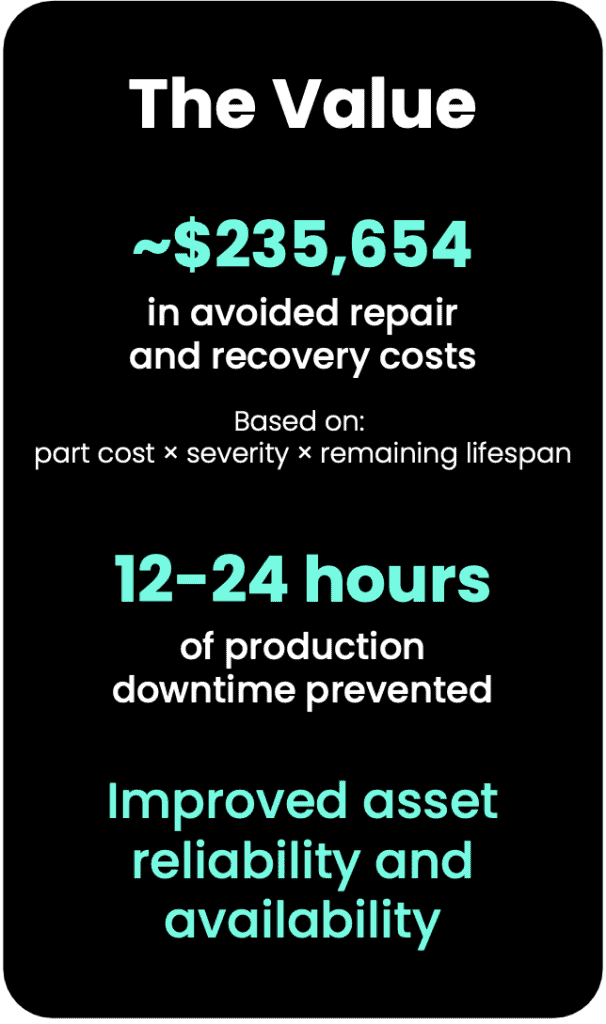

Results

- Zero unplanned downtime

- Radiator degradation detected early – before impact on performance

- Continuous production maintained without operational disruption

- Improved ConMon efficiency by eliminating false alarms and noise

Summary

In large mining operations, where fleets generate thousands of OEM alerts weekly, it’s easy for real mechanical issues to get buried in the noise.

This case highlights how DataMind AI™ goes beyond traditional monitoring, cutting through the alert overload to detect the true root cause of faults.