Case Study: Radiator Blockage Detected by DataMind AI™ in CAT 793D

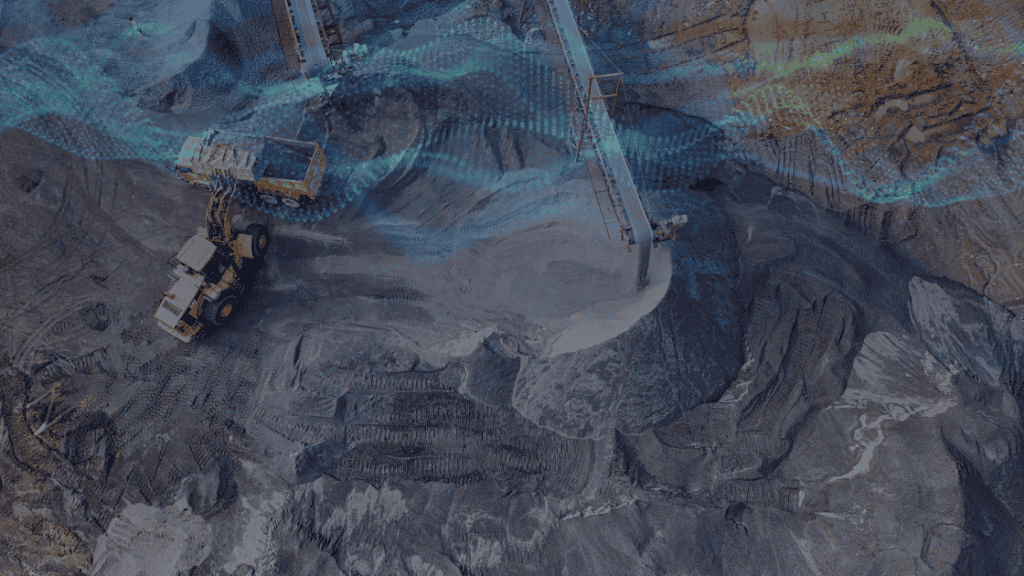

By Razor Labs 7 min read SHARE Overview DataMind AI™ for Mobile Fleet was deployed at a large mining operation to monitor CAT 793D haul trucks and detect mechanical issues hidden beneath thousands of OEM alerts. In a single week, the CAT fleet generated 23,132 OEM alerts, including 655 on one 793D haul truck making […]

IMARC 2025 Keynote Panel: How Collaboration, Technology and Innovation are Accelerating Decarbonisation and Productivity

IMARC 2025 Keynote Panel: Innovation at the Core of Decarbonisation and Productivity By Razor Labs 6 min read SHARE https://youtu.be/wG3qHDVmEjQ?si=y8pLdsaMgEjRs3qs At IMARC 2025 in Sydney, Razor Labs’ Chief Business Officer, Tomer Srulevich, participated in a keynote panel titled “How Collaboration, Technology and Innovation are Accelerating Decarbonisation and Productivity.” The discussion brought together leaders from EY, […]

Case Study: DataMind AI™ Detects Early Fuel Injector Degradation in CAT 793D Haul Truck

By Razor Labs 7 min read SHARE Overview DataMind AI™ for Mobile Fleet was deployed at a large coal mining operation to continuously monitor heavy mobile equipment in real time and deliver actionable health insights across the fleet. During routine operation, the fleet generated a very high volume of OEM alarms. In a single week, […]

Razor Labs Q4 2025 Summary Newsletter

By Razor Labs 5 min read SHARE In 2025, Razor Labs delivered measurable results across multiple sites and regions, helping mining and heavy industry operators shift from reactive maintenance to data-driven, predictive operations. Throughout the quarter, we introduced key product advancements, expanded deployments across four continents, and strengthened partnerships with industry leaders – demonstrating how […]

Razor Labs Launches DataMind AI™ 4.5

By Razor Labs 5 min read SHARE Razor Labs Launches DataMind AI™ 4.5, a Major Leap Forward in Predictive Maintenance and Fleet Management for Mining Operations SYDNEY, Dec. 11, 2025 /PRNewswire/ — Razor Labs (TASE:RZR) announces the launch of DataMind AI™ 4.5, a powerful upgrade to its predictive maintenance platform designed for mobile fleet management and fixed assets across mining operations. Built through continuous […]

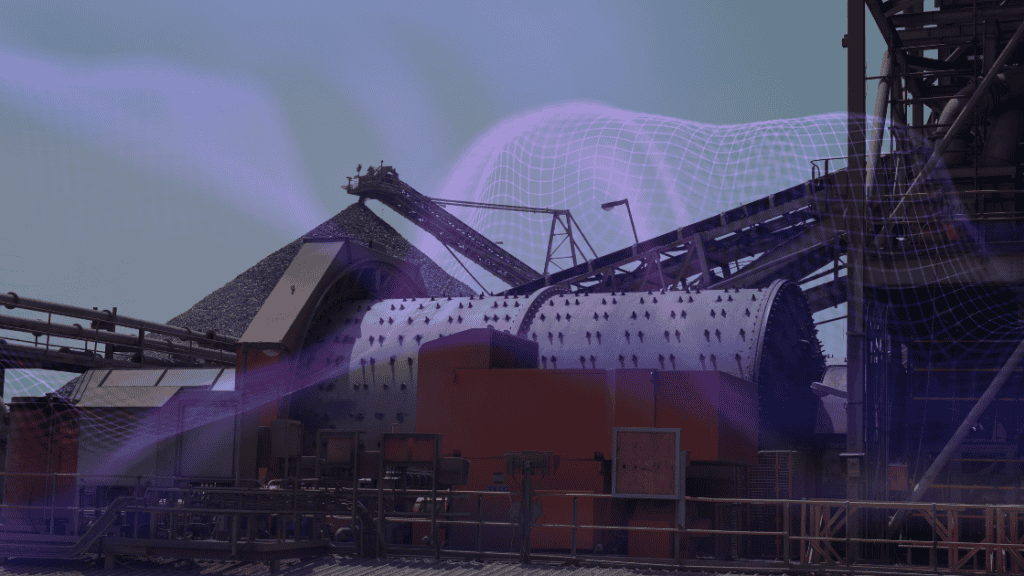

Razor Labs hones advantage at cutting edge of mining machine health

By Razor Labs 5 min read SHARE As featured in Mining Beacon: Coming from a family of doctors, Michael Zolotov knows a fair bit about the value of holistic health monitoring and pre-emptive actions. After a decade of exposure to mining maintenance problems – and opportunities – he sees the future of machine health through a similar […]

IMARC 2025 Keynote: Digital Transformation in Mining Operations

IMARC 2025 Keynote: Digital Transformation in Mining Operations By Razor Labs 6 min read SHARE https://youtu.be/780LxsMCFU4 At IMARC 2025, Razor Labs Director of Marketing Liel Anisenko sat down with Jake Thornton, Director, Mining Operations Advisory at KPMG Australia, for a candid conversation on one of mining’s biggest challenges: how to turn the promise of digital […]

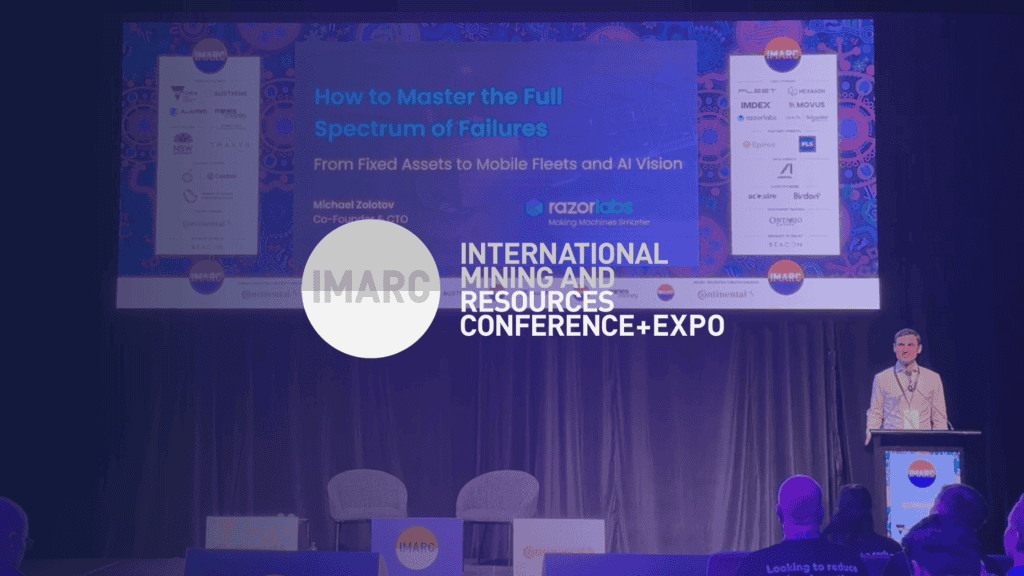

IMARC 2025 Keynote: How to Master the Full Spectrum of Failures in Mining

IMARC 2025 Keynote: How to Master the Full Spectrum of Failures in Mining By Razor Labs 6 min read SHARE https://youtu.be/dsla5v87xrY At IMARC 2025, Razor Labs CTO and co-founder Michael Zolotov presented a keynote “Mastering the Full Spectrum of Failures: From Fixed Assets to Mobile Fleets and AI Vision.” Drawing on insights from mining sites across […]

Razor Labs is creating a new era in mobile fleet reliability

By Razor Labs 5 min read SHARE After successful deployments across South America and Africa, Razor Labs, is extending its DataMind AI for mobile fleet to the Australian market. DataMind AI is designed to deliver capabilities beyond original equipment manufacturer (OEM) and existing fleet health systems, detecting failures weeks earlier, tracing root causes with multi-sensor […]

Razor Labs Announces Strategic Partnership with Process Automation to Accelerate AI-Driven Digital Transformation in South African Mining

By Razor Labs 5 min read SHARE Razor Labs, a global leader in AI-powered predictive maintenance for heavy industries, has announced a strategic partnership with Process Automation (Pty) Ltd, a well-established provider of industrial instrumentation and automation systems. As Razor Labs’ official partner and system integrator in Africa, Process Automation will support the rollout of DataMind AI™, […]