December 15, 2025

In 2025, Razor Labs delivered measurable results across multiple sites and regions, helping mining and heavy industry operators shift from reactive maintenance to data-driven, predictive operations.

Throughout the quarter, we introduced key product advancements, expanded deployments across four continents, and strengthened partnerships with industry leaders – demonstrating how AI turns operational data into actionable insights and tangible impact.

Innovation Milestones

Razor Labs launches new version of its Predictive Maintenance System, DataMind AI™

“DataMind AI™ 4.5 gives reliability engineers a simpler, more powerful way to manage sensor data and deliver clearer asset health visibility.” – Assaf Eden, VP Product

This version delivers clearer machine health visibility, faster diagnostics, and stronger predictive maintenance capabilities to help maintenance teams act faster and smarter. Read the full article here>>

Industry Recognition

Razor Labs wins the prestigious 2025 Newsweek AI Impact Awards

We’re honored to be recognized in the AI Science & Engineering – Best Outcomes category, spotlighting the real-world results of DataMind AI™ in mining operations. This global award reflects the strength of our engineering and the tangible impact of AI in the field. Learn more>>

Real-World Impact

As the year progressed, DataMind AI™ continued to deliver real-world impact – helping maintenance teams detect faults early, reduce downtime, and protect critical operations.

Below are some of the most recent failures we prevented, demonstrating how AI enables proactive maintenance with measurable impact.

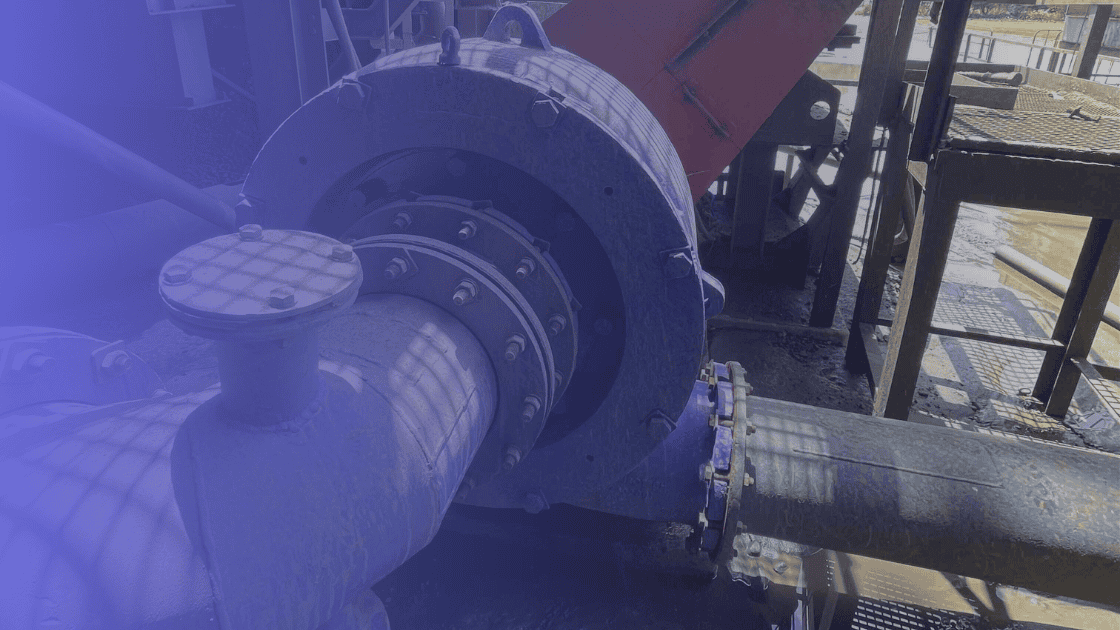

Preventing Slurry Pump Motor Failure with DataMind AI™

- Unplanned downtime prevented: 5 hours

- Estimated savings: $120,000

- Download the full case study here>>

DataMind AI™ Detects Gear Friction in Compressor Gearbox

- Unplanned downtime prevented:30 hours

- Estimated savings: $2,200,000

- Download the full case study here>>

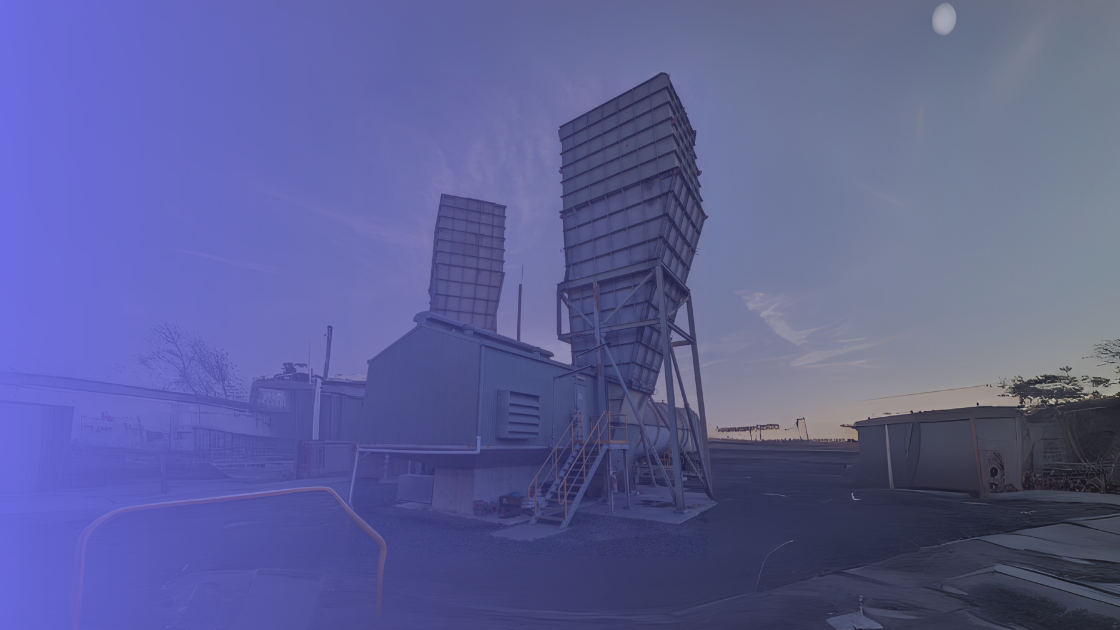

DataMind AI™ Detects Lubrication Fault in Ventilation Fan

- Unplanned downtime prevented: 7 hours

- Estimated loss savings: $210,000

- Download the full case study here>>

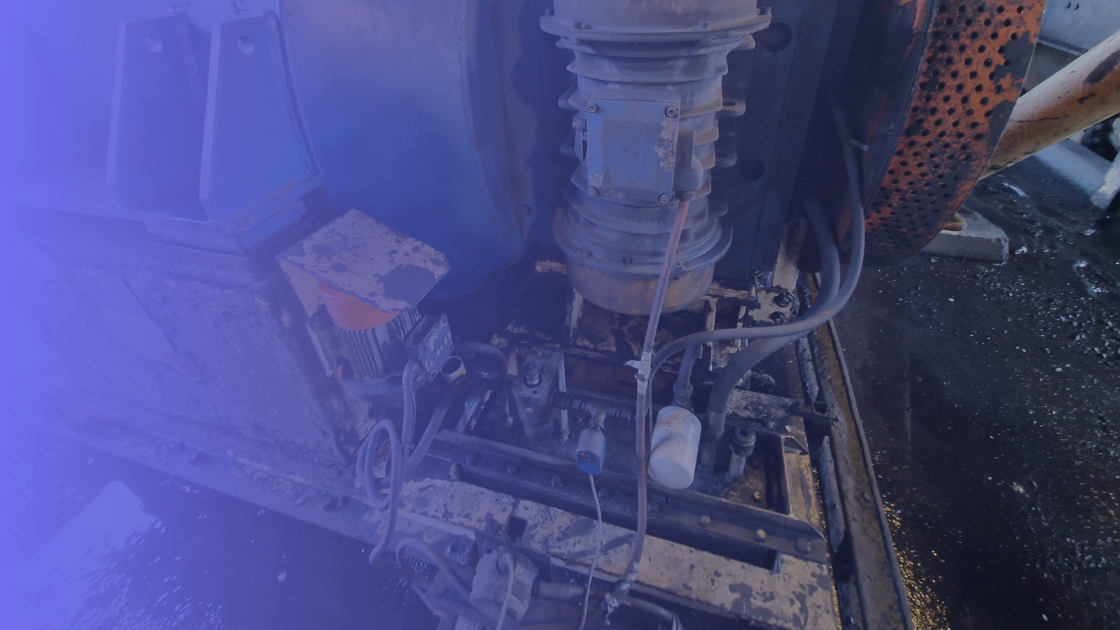

Hidden Friction in Lubrication Pump – Prevents Centrifuge Failure

- Unplanned downtime prevented: 7 hours

- Estimated loss savings: $240,000

- Download the full case study here>>

Featured In Q4

Industry Events

IMARC 2025

Razor Labs joined IMARC 2025 in Sydney, where CTO & Co-Founder Michael Zolotov delivered a keynote titled “How to Master the Full Spectrum of Failures in Mining”, highlighting how AI transforms failure detection across fixed assets, mobile fleets, and visual inspections. Read more >>

Coaltech Ideation Summit 2025

Razor Labs took part in the Coaltech Ideation Summit in South Africa, where our local team showcased how predictive maintenance powered by DataMind AI™ can drive long-term innovation and operational resilience in coal mining. Read more >>

Closing the Year, Looking Forward

As the year ends, we wish you and your loved ones a warm holiday season and a strong start to the year ahead. Thank you for being part of our journey.