Real-Time Visual Intelligence for Mining Operations

Avoid Catastrophic Failures Invisible to any Other Sensor

Smarter vision. Faster insights. Fewer failures.

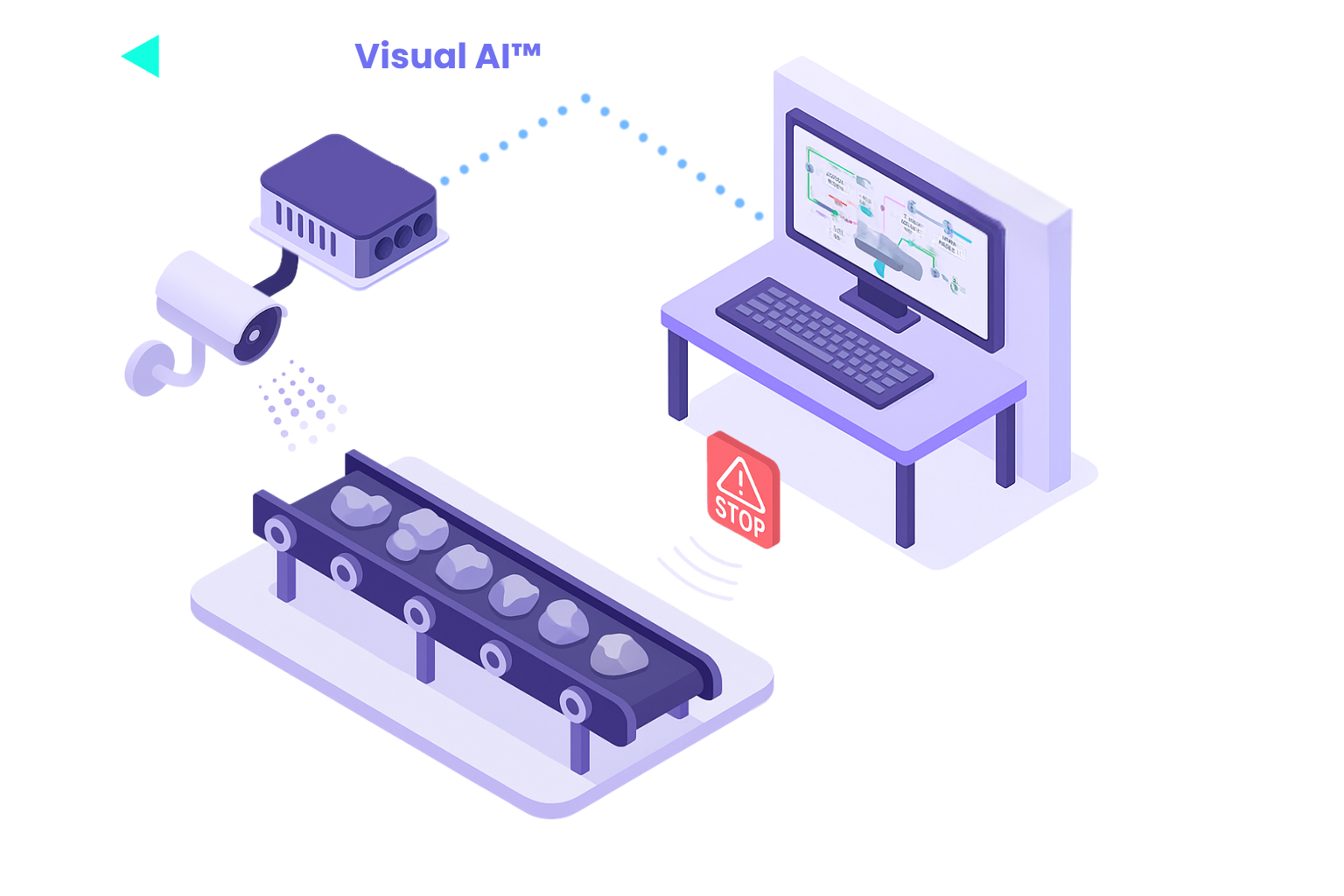

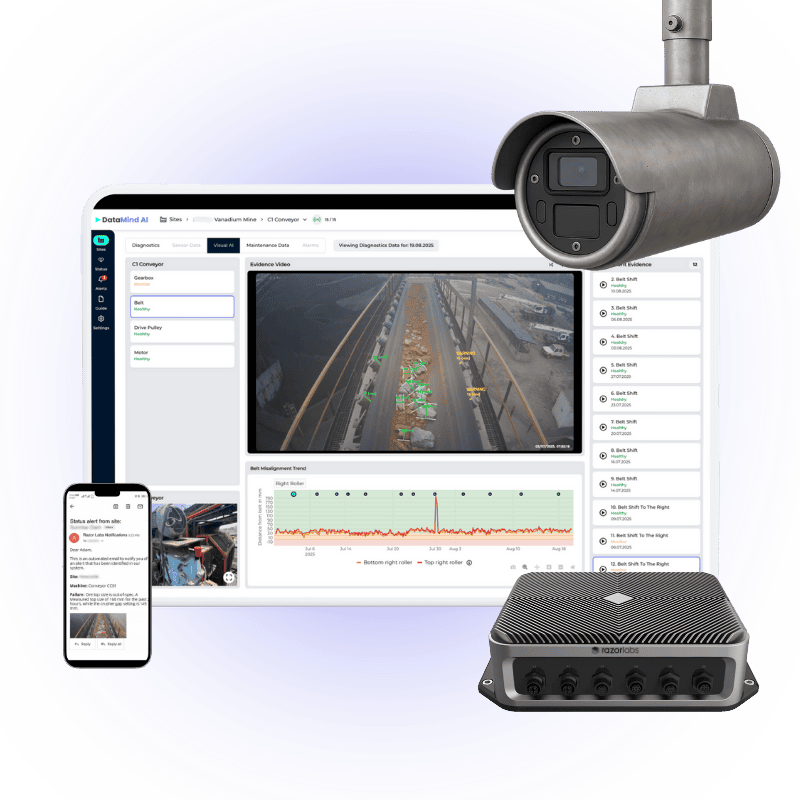

DataMind Visual AI™ is an AI-enabled monitoring system that uses industrial cameras integrated with cutting-edge AI to deliver real-time visibility into critical failures and process inefficiencies across conveyors, crushers, feeders, and flotation cells.

The system alerts weeks before deterioration develops into a failure and, if selected, can automatically stop the conveyor in unpredictable events to minimise damage.

It is fully integrated with the DataMind AI™ platform, which monitors the rest of the equipment using oil, vibration, motor current, and pressure data – ensuring complete, holistic coverage of all potential failure modes across the site.

AI-powered monitoring of a wide range of deteriorations and process inefficiencies that cannot be detected by other sensors.

Detects oversize boulders in real time – before they jam crushers or block chutes.

Identifies gradual lateral drift to prevent edge wear or belt run-off.

Real-time monitoring of bubble size and color to maximise recovery efficiency and maintain process stability.

Automatically detects and monitors belt clip and splice conditions to save manual inspections and prevent belt rips.

Certain unpredictable events – such as a single oversized rock or a sudden belt rip caused by contamination – can’t be foreseen, yet require an instant response to avoid major damage.

Stopping the conveyor immediately can significantly reduce repair time, cost, and belt damage.

DataMind Visual AI™ integrates with SCADA, allowing operation teams to configure automatic belt stops in such high-risk scenarios, ensuring faster action and better protection for critical assets.