Razor Labs is creating a new era in mobile fleet reliability

By Razor Labs 5 min read SHARE After successful deployments across South America and Africa, Razor Labs, is extending its DataMind AI for mobile fleet to the Australian market. DataMind AI is designed to deliver capabilities beyond original equipment manufacturer (OEM) and existing fleet health systems, detecting failures weeks earlier, tracing root causes with multi-sensor […]

Australian Mining – Razor Labs is creating a new era in mobile fleet reliability

Razor Labs is an AI predictive maintenance technology company and a Triple Category Winner in the 2024 Mining Technology Excellence Awards

Razor Labs Announces Strategic Partnership with Process Automation to Accelerate AI-Driven Digital Transformation in South African Mining

By Razor Labs 5 min read SHARE Razor Labs, a global leader in AI-powered predictive maintenance for heavy industries, has announced a strategic partnership with Process Automation (Pty) Ltd, a well-established provider of industrial instrumentation and automation systems. As Razor Labs’ official partner and system integrator in Africa, Process Automation will support the rollout of DataMind AI™, […]

Yahoo Finance Highlights Razor Labs & Process Automation Partnership in South Africa

Razor Labs is an AI predictive maintenance technology company and a Triple Category Winner in the 2024 Mining Technology Excellence Awards

Predictive Maintenance with AI: Razor Labs on the Reliability 4.0 Podcast

by Razor Labs 5 min read SHARE From Reactive to Predictive: How AI is Transforming Equipment Reliability In this episode of the Reliability 4.0 Podcast, Razor Labs’ CTO & Co-Founder Michael Zolotov, joins host Sebastian Traeger, to discuss how AI is changing the way mining and industrial teams approach maintenance and reliability. Michael introduces DataMind […]

Case Study: DataMind AI™ Detects Gear Friction in Compressor Gearbox, Preventing Catastrophic Failure

By Razor Labs 7 min read SHARE Overview DataMind AI™ was deployed at a vanadium mining site to monitor fixed rotating assets across production-critical systems. Among these assets was a key compressor, one of the most essential machines on site. In mid-June 2025, DataMind AI™ flagged an Alarm on the compressor’s gearbox, identifying increasing vibration […]

Case Study: Preventing Slurry Pump Motor Failure Through Early Detection with DataMind AI™

By Razor Labs 7 min read SHARE Overview Razor Labs DataMind AI™ was monitoring critical rotating equipment at a vanadium mining site, including one of the site’s main slurry pumps. This pump is a critical component in one of the site’s two parallel processing lines. A failure would have forced a shutdown of the entire […]

PODCAST: Razor Labs on “Dig Deep Mining Podcast” – How AI is Changing Mining Operations

by Razor Labs 5 min read SHARE In this episode of the Dig Deep Mining Podcast, Razor Labs’ CTO & Co-Founder, Michael Zolotov, joins host Rob Tyson to explore how artificial intelligence is reshaping predictive maintenance in the global mining sector. Michael shares the story behind Razor Labs’ flagship product, DataMind AI™, and how it […]

Case Study: DataMind AI™ Flags Hidden Friction in Lubrication Pump – Prevents Centrifuge Failure

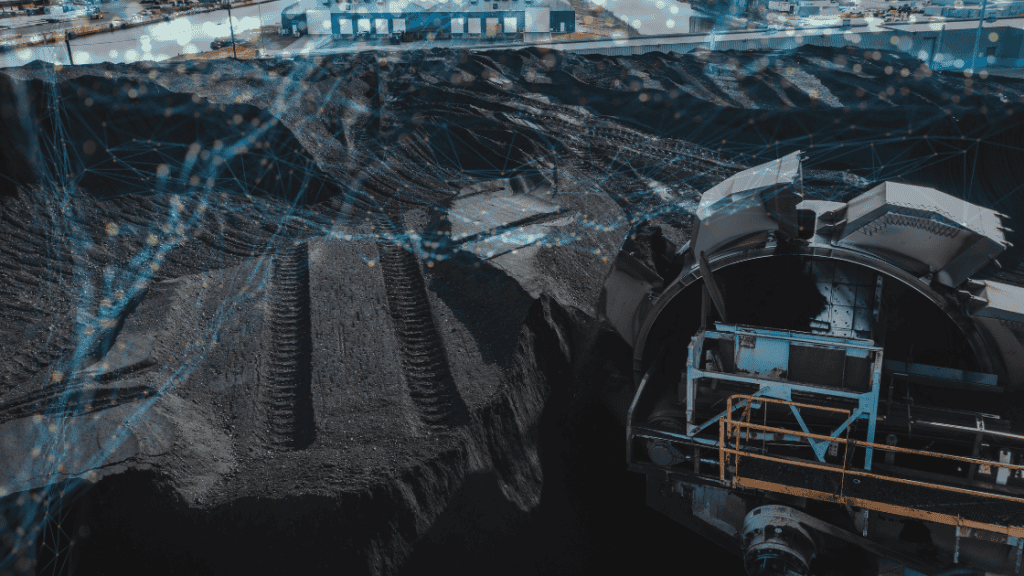

By Razor Labs 5 min read SHARE In coal mining, high-speed centrifuges play a critical role in reducing moisture content in fine coal during the dewatering process. But these machines rely on something deceptively simple: a dedicated lubrication pump that keeps their bearings running smoothly. At one site, DataMind AI™ was deployed to monitor the […]

Webinar: Data-Driven Maintenance Decisions – Lessons from Coal Mining Deployments

by Razor Labs 6 min read SHARE Smarter Maintenance in Coal Mining with DataMind AI™ Predictive maintenance in coal mining is challenging – high loads, abrasive materials, and remote environments create a perfect storm for unplanned downtime. In this recorded webinar, produced in collaboration with Austmine, we explore how DataMind AI™ is helping operations move […]